info@emersonapparatus.com

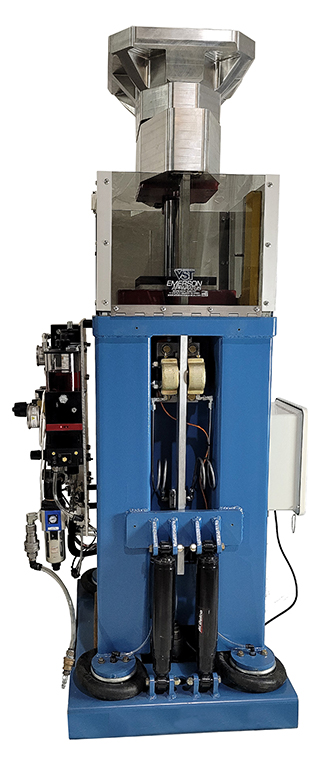

Emerson’s Pneumatic Shock Machines are available in multiple configurations including Vertical and Horizontal options.

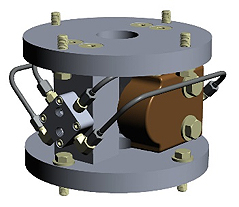

The Mouse Trap Amplifier option produces very high G, short duration test levels. Emerson Apparatus’s Pneumatic shock machines are used by leading firearms and optics manufactures for high-cycle “live fire” shock events.

Highlights

- Don’t “slinky” your armature on 100g 6ms shock pulses—Our pneumatic shock machines save the wear and tear on your shaker from the hard testing of high velocity classical shock

- 100 to 2,500 lb capacity machines available

- 30,000g capability (MIL-STD 883)

- High resolution data acquisition, closed-loop control for high-cycle testing

- Horizontal capability

- Square-wave and trapezoidal pulses by nitrogen charged pistons

- Terminal peak saw-tooth (TPST) tests performed with molded lead cones

- Superior air-hydraulic brakes, closed-loop control which modifies the pulse to remain in tolerance with high pulse counts, heating, and changing durometer of the programmer pads

Description of Operation

Mousetrap Amplifier

Our Pneumatic Shock Machines use compressed air to accelerate the carriage toward the impact surface. Elastomer pads between the carriage and impact surface are used to produce half-sine pulses. Pneumatic cylinders and lead pellets are used for trapezoidal and terminal sawtooth pulses respectively. The design of the half-sine programmer essentially determines the duration or Delta T while air pressure and drop height provide the energy for the magnitude or G level of the pulse.

- The whole process is controlled by Emerson’s “ShockTool” software. ShockTool provides machine control and data acquisition/analysis in one package and is included with each machine.

- The core structure of the machine is a heavy steel weldment filled with reinforced concrete. This structure forms the reaction mass and is supported by passive air springs to isolate any shock load from the floor. Viscous dampers arrest the air spring oscillations just like the shock absorbers in a car.

- Heavy duty threaded inserts installed on the working surface of the solid aluminum carriage provide the hole pattern used to hold items or fixtures for test. The carriage is supported and guided by the main cylinder. Hydraulically actuated friction brakes hold the carriage in the drop position while air pressure builds in the main cylinder.

- Each Pneumatic Shock Machines is equipped with an air amplifier to produce charge pressures well above the supply pressure. The brakes are released once the desired charge pressure is attained and the carriage accelerates towards the impact surface. Following the impact event, the brakes activate during the rebound to arrest the carriage and prevent a double hit.

2,500lb Pneumatic Shock Machine – Slow Motion

Models

| Pneumatic Shock Machine | Table Options Working Surface in Inches X Inches | Power Requirements | ||||||

| Payload LBS | 09 x 09 | 16 x 16 | 18 x 18 | 24 x 24 | 30 x 30 | 40 x 40 | 60 x 60 | Control Power Min Air Requirement** |

| 100 | X | X* | 110-220 VAC 90W 90 PSI @ 5CFM | |||||

| 500 | X | X | X | 110-220 VAC 90W 90 PSI @ 10CFM | ||||

| 1000 | X | X | X | X* | 110-220 VAC 90W 90 PSI @ 10CFM | |||

| 2500 | X | X* | 110-220 VAC 90W 90 PSI @ 30CFM | |||||

| Options | Notes | |||||||

| 0404MTA | Bolt On | Bolt On | Bolt On | Bolt On | Bolt On | Bolt On | Bolt On | 0.2ms-1.5ms up to 5000g Half-sine |

| 0909MTA | Built In | Built In | Bolt On | Bolt On | Bolt On | Bolt On | Bolt On | 0.5ms-3.0ms up to 2000g Half-sine |

| VH Vertical Horizontal | X | X | X | Machine can be used in either mode | ||||

| SW Square Wave | X | X | X | X | X | Not Available on PSM100 | ||

| TSP Terminal Sawtooth Pulse | X | X | X | X | X | X | X | Achieved by impacting lead pellets |

* Working Surface is achieved via Head Plate / Head Expander

** The cycling rate increases with more CFM

Emerson Apparatus refurbishes all AVEX/AVCO models of pneumatic shock machines: the SM-105, SM-110 & SM-220.

Highlights

- Complete tear down/overhaul of the machine

- All micro-switch controls replaced with PC-based controls

- All new air-to-hydraulic braking systems

- Full data acquisition and closed-loop control package

- Refurbished machine comes with 1 year warranty

Old Machine ⇒

Refurbished Machine

New Power Pallet

New Air to Hydraulic Brake System

Refurbished AVEX SM-110

Refurbished AVEX 110

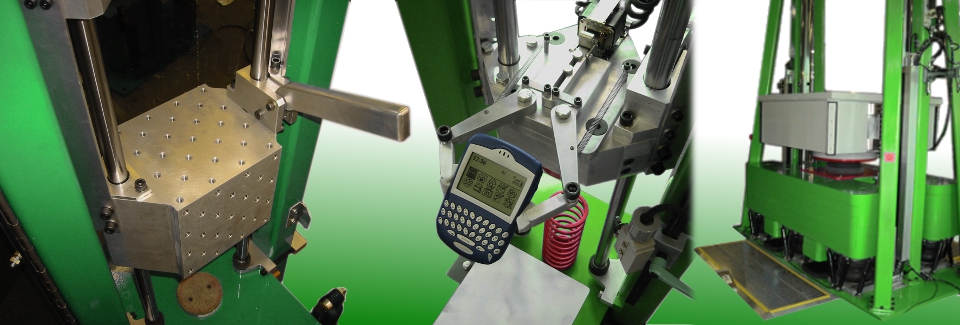

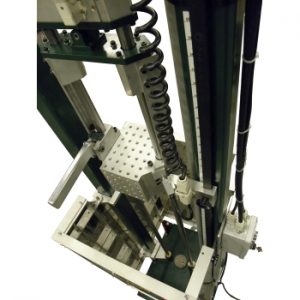

Emerson’s Free-Fall Shock Machines produce classical shock waves by dropping a table guided by polished shafts onto a programmer backed up by a solid steel reaction mass. The reaction mass is suspended on springs or airsprings and damped by shock absorbers to isolate the shock loads from the supporting floor. Emerson Free-Fall Shock Machines range from 5″ to 63″ work area and up to 5000 lbs payload.

Highlights

- Pulse shape and duration achieved with elastomer pads for half-sine

- Amplitude achieved by adjusting drop height

- Square-wave and trapezoidal pulses by nitrogen charged pistons

- Terminal peak saw-tooth (TPST) testing performed with lead cones

Description

Description

The FSM20-0505 and FSM50-0707 Free-Fall Shock Machines provide three mounting surfaces and produce excellent data in the short time high g level range (1500g@0.5ms is no problem). The table drop height can be set at a user-defined height for shock pulse repeatability.

The acceleration level is determined by the drop height while time duration is a function of the installed programmer; elastomer pads for half-sine, lead pellets for sawtooth, and nitrogen pistons for square wave pulses.

A shock amplifier or MTA can be added for higher g levels and for extremely high g levels, a bungee assisted drop option is available.

The larger Free-Fall Shock Machines are built for high payload capacities and are operated hydraulically via PC Touchscreen with an active hydraulic braking system to prevent double hits.

FSM200 1818 Bungee Test Slow-MoFreefall Shock Machine 5000

Models

| Free-Fall Shock Machine | Table Options Working Surface in Inches X Inches | Power Requirements | ||||||

| Max Payload LBS | 04 x 04* | 05 x 05 | 07 x 07 | 15 x 15 | 30 x 30 | 40 x 40 | 60 x 60 | 50/60Hz |

| 5 | X | 110-120VAC 1 PH 10Amp | ||||||

| 20 | X | 110-120VAC 1 PH 10Amp | ||||||

| 50 | X | 110-120VAC 1 PH 10Amp | ||||||

| 500 | X | X | 208-240VAC 3PH 20Amp | |||||

| 1000 | X | 208-240VAC 3PH 20Amp | ||||||

| 5000 | X | 380-480VAC 3PH 30Amp | ||||||

* Extremely High G 30000g@0.05ms from 0404 MTA mounted on FSM20-0505 base machine w/bungie assist