info@emersonapparatus.com

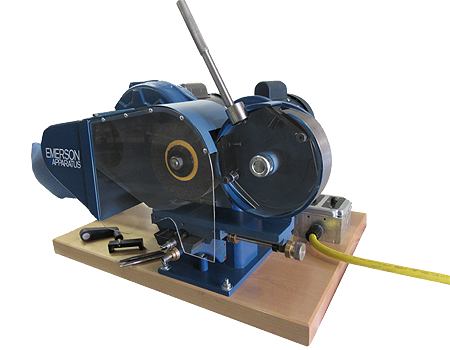

Emerson’s Rubber Buffing Machine is designed for preparing elastomer samples to a uniform thickness in accordance with the ASTM 3183 (for performing tensile, air aging as with the Emerson Geer Oven or other physical tests). Features a self-contained suction blower and dust collection bag to take away and collect material removed during buffing, ensuring a dust free work area. Also supplied is a diamond wheel dressing tool to quickly and accurately dress the wheel to a uniform flat rotary surface. A micrometer dial feed, accurate to within .002″, ensures uniform and repeatable results.

Features

- Prepare elastomer samples to a uniform thickness in accordance with the ASTM 3183

- Self-contained suction blower and dust collection bag takes away and collects material removed during buffing, ensuring a dust-free work area

- Comes with diamond wheel-dressing tool to quickly and accurately dress the wheel to a uniform flat rotary surface

- Micrometer dial feed, accurate to within .002″, ensures uniform and repeatable results

- Supplied with a 5″ diameter/36 grit grinding wheel (other sizes and grits are available on request)

- Flat platens sold as accessories for flat, stable sample use (see below)

- Rotary platens sold as accessories for irregular shapes such as wire, cable, and hose (see below)

Specifications

- Weight 55 lbs

- Shipping Weight 85 lbs

- Volume 7 cu ft

- Electrical 230/115 VAC 60Hz, 230/115 VAC 50Hz

Accessories/Options

Platens are necessary to hold the samples for buffing. They are sold as accessories and should be selected based on anticipated testing needs. Platens are available in two different styles and two separate sizes for each style. Flat platens are designed for samples that will lay flat, and the rotary platens are designed for irregular samples that must be held down by wrapping them around a drum. All platens are equipped with a snap clamp for quick and easy installment and removal of samples.

Short Flat Platen Sizes

Short Flat Platen Sizes

For flat, stable samples

Length of samples 5.5″ to 6.5″

Length of buffed area 2″ Long Flat Platen Sizes

Long Flat Platen Sizes

For flat, stable samples

Length of samples 7″ to 8″

Length of buffed area 4″ Short Rotary Platen Sizes

Short Rotary Platen Sizes

For irregular samples (wire, cable, hose, etc.)

Length of sample 6″ to 6.5″

Length of buffed area 4″ Long Rotary Platen Sizes

Long Rotary Platen Sizes

For irregular samples (wire, cable, hose, etc.)

Length of sample 16.5″ to 18″

Length of buffed area 11″.

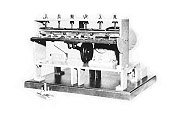

The Model AR2 Ross Rubber Flexing Machine is designed to determine the resistance of vulcanized or synthetic elastomers to cut growth. It conforms to ASTM Method D1052.

Features

- Can test six pairs of samples simultaneously (12 total)

- Tests sample thicknesses ranging from 1/8″ to 1/2″

- Frequency of the flexures is 100 cycles per minute

- Six-digit counter tallies actual flexures

- Self-contained with a 115 volt, 1/3 HP gear motor

Specifications

- Net weight 45 lbs

- Shipping weight 55 lbs

- Dimensions 31″ X 26″ X 19″

- Cubic 7.3 cu ft

- Volts 115VAC

- Motor 1/3 HP gear motor

Accessories/Options

A piercing tool is available to make an accurate cut conforming to ASTM D1052. Contact sales for information regarding this piercing tool.

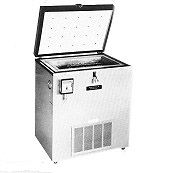

The Model AR6 Ross Rubber Flexing Machine is designed to determine the resistance of vulcanized or synthetic elastomers to cut growth. It conforms to ASTM Method D1052. For low-temperature flexing, the AR6 flexer is mounted in a cold chamber capable of sustaining -40°F during operation.

Features

- For low-temperature flexing

- Mounted in a cold chamber capable of sustaining -40°F during operation

- Stainless steel manufacture prevents rust due to condensation

- Motor is mounted outside the chamber and drives the flexer by way of a coupling

- Can test six pairs of samples simultaneously (12 total)

- Tests sample thicknesses ranging from 1/8″ to 1/2″

- Frequency of the flexures is 100 cycles per minute

- Six-digit counter tallies actual flexures

- Self-contained with a 115 volt, 1/3 HP gear motor

- Digital temperature controller

- Audible/visual alarm

- Key-locking door and casters

- Pre-assembled and furnished ready for use

- Complies with ASTM D1052 and FED CCC-C-501A (coated cloth)

Specifications

- Temperature range +70°F to -40°F

- Net weight 500 lbs

- Shipping weight 595 lbs

- Cubic 9.4 cu ft

- Internal dimensions 19″H x 49″W x 17″D (includes sublids)

- External dimensions 41″H x 60″W x 28″D

- Volts 115VAC

Accessories/Options

Emerson also manufactures aging apparatus conforming to ASTM D572 and D573. Please contact sales for details.