info@emersonapparatus.com

(For a larger view, click on the image of each compression tester)

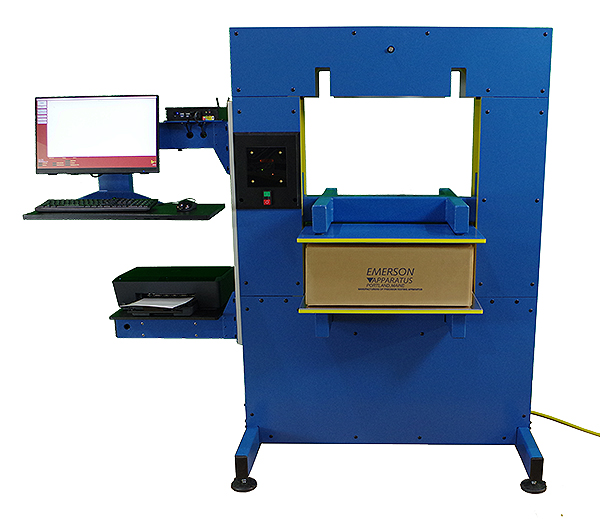

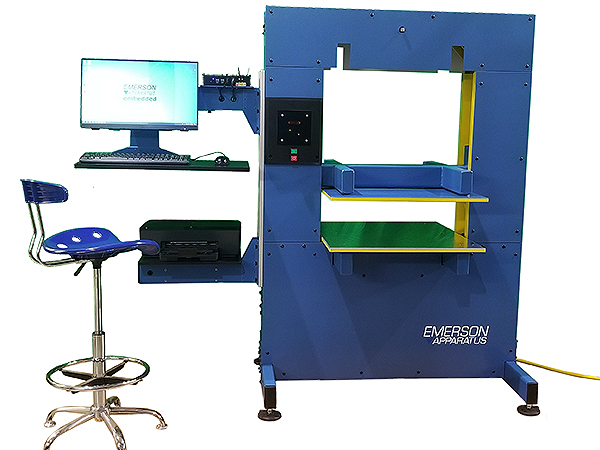

The Emerson Model 6200 Compression Tester was created for the performance testing of shipping containers. Designed in accordance with the requirements of ASTM D642 and TAPPI T804 equipment specifications, its functionality allows for the performance of a variety of test procedures, including T804, D642, D4169, 49 CFR, Item 180, and ISTA.

mounts shown in picture are optional

Features

- Emerson Compression Tester dedicated software package takes full control of the operation of the tester

- Data management is easy with Emerson’s statistical process control (SPC), histograms, and control charts

- Extremely rigid, parallel and flat platens engineered and built for precise yet rugged duty

- Enhanced, dedicated Emerson Compression Tester Software, such as “Test Explorer,” for graphical data allows the user to create unlimited customer box type and identification numbers for products being tested. Also enhanced data management

- Safety features include overload protection, upper & lower limit switches, rapid travel, applied load machine stop*

- Software stop limits automatically recalled for the box you are testing

- Industrial Ethernet allows for high speed data transfer, no-loss communications, and inter-system groups

- Comply with ISTA, ASTM, TAPPI and other international and industry recognized standards groups

- Rapid platen return and settable positioning allows for rapid, repetitive testing

- Automatic Tare

- Temperature and humidity module included

- Imperial and Metric capabilities

- Calibrated in accordance with ASTM Method E4

- Standard Language: English

- Easy test value entry boxes, updated error handling, multiple chart overlays, and much more

- Set maximum and minimum height of the sample and deflection displays at all times

- Enhanced linear motion system rigidity

- Increased platen stiffness

- Maximized dynamic parallelism

- Enhanced shielded machine enclosure

- Reduced equipment footprint

- Integrated adjustable operator workstation

- Enhanced ergonomics: load/unload/operate from same position

- Advanced motion system

- Green high torque motor

- Remote mounted temperature/humidity probe

- Dual plane shielding

- Pluggable electrical panel for turnkey replacements

- Enhanced cable management

- Internal guarding

- Near silent operation

- Adaptable modular frame design

- Solid state industrial controller

- Microsoft Windows 10 Professional

- User WiFi and LAN connections available standard

- 10 point capacitive touch screen

- Complimentary keyboard and mouse tray

- Complimentary stand-up compatible stool

- Caster Kit available (request pricing)

- Test automation option compatible

Software/Controller Features

Software/Controller Features

All Compression Tester Models come with our Dedicated Computer Controller System, Color Printer, Color Monitor, and our pre-loaded Emerson Compression Tester Software Program (Windows Operating System).

- Dedicated Compression Tester software package

- Windows Operating System

- High-speed computer

- 21″ Flat Panel color display

- Color printer

- Super imposed plotting for viewing multiple test curves

- Program recovery allows the user to recover their Compression Tester software and calibration information

- Enhanced tests have been updated, including a 10-point profile test allowing the user to set up to 10 distinct loads

- Full software support for Compression Tester software versions 5.15 and up

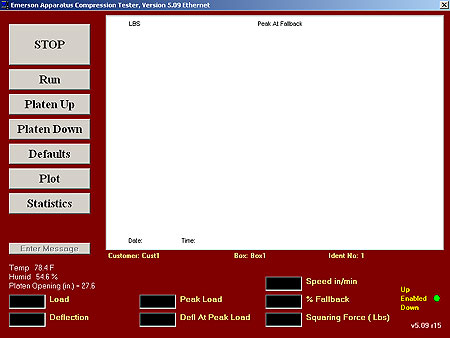

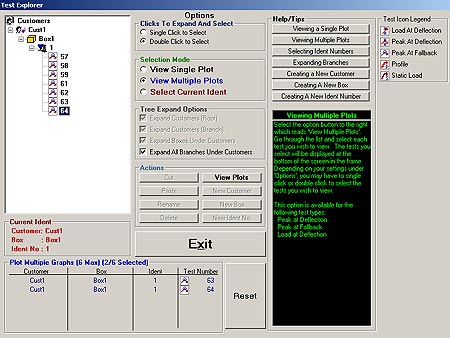

Preview Software

Preview Emerson’s Compression Tester Software which uses familiar Windows-based screens and navigation aids to provide an intuitive and user-friendly interface to your Compression Tester equipment. Data management is easy with our NIST-approved statistical process control (SPC), histograms, and control charts.

Preview +

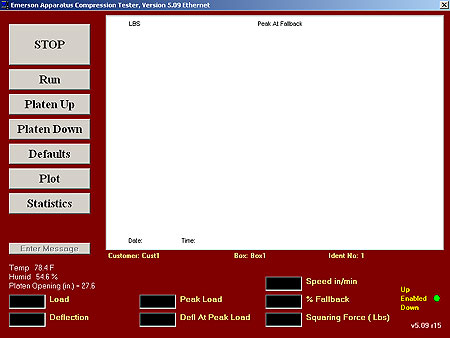

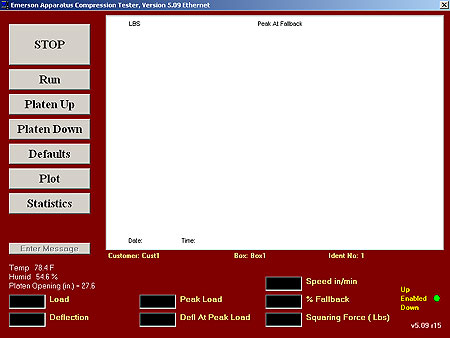

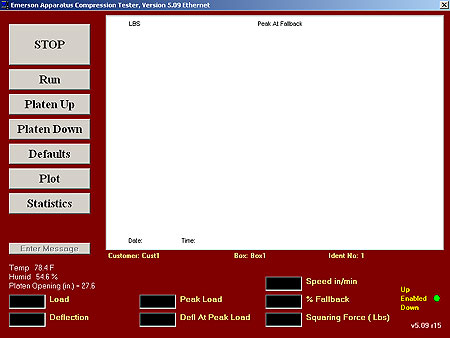

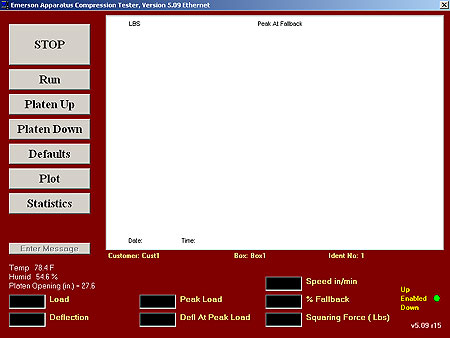

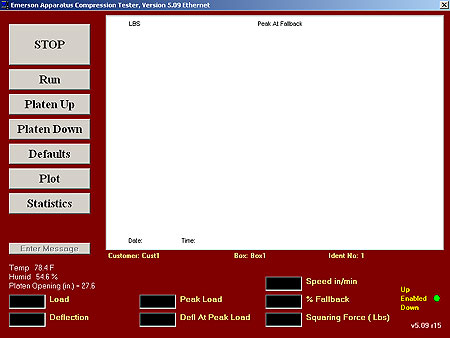

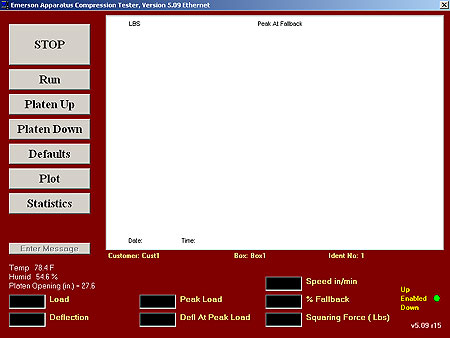

MAIN MENU–With just a few key strokes, the Compression Tester’s “Main Menu” screen allows users to select test types, run tests, control the compression tester platen, search statistical reports, plot graphs, and/or view graphs on screen.

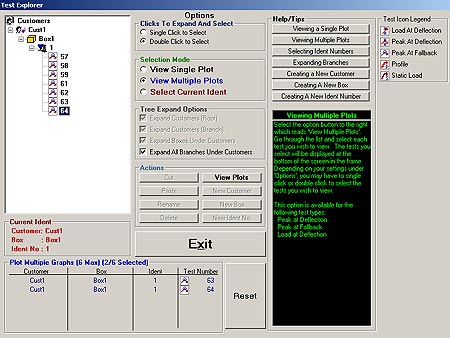

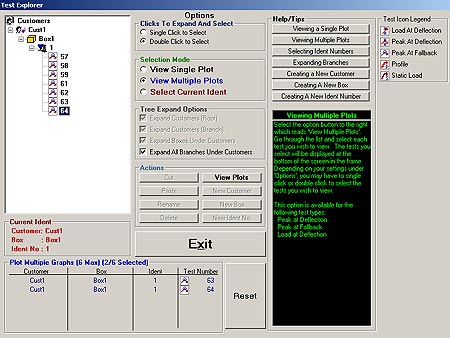

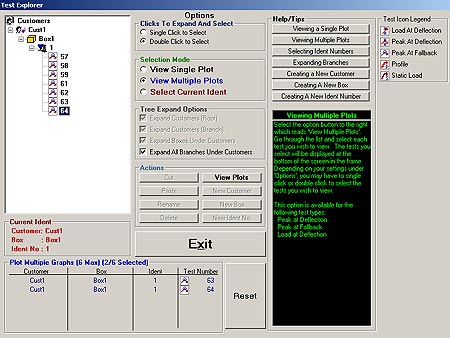

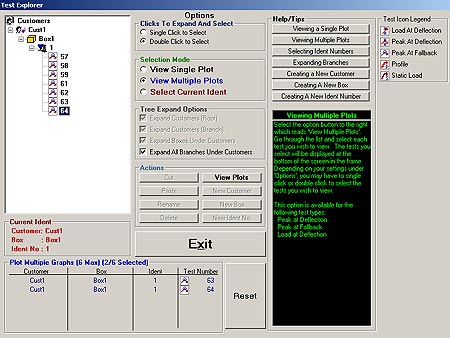

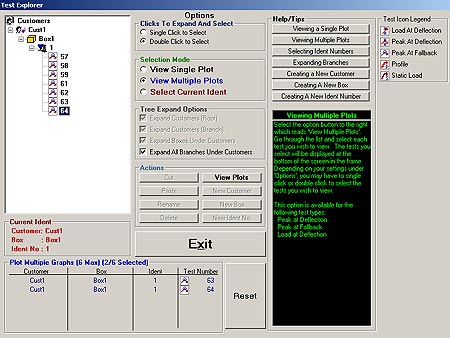

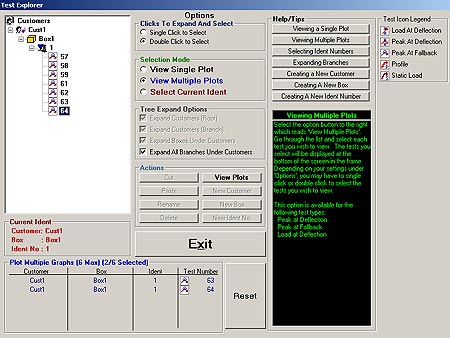

TEST EXPLORER–With the “Test Explorer” feature, users set up customer box types with specific parameters for each test. Users can also review desired test results and view single plots or superimpose multiple plots on one graph.

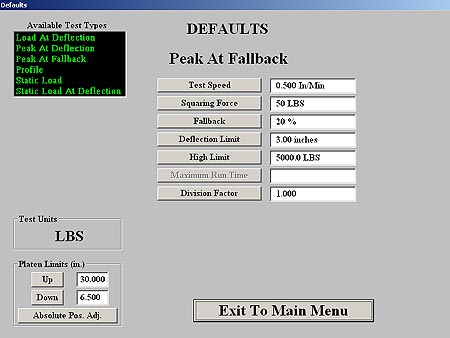

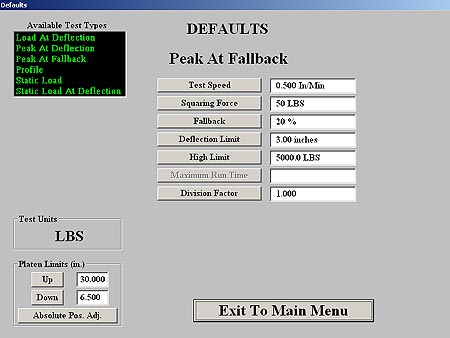

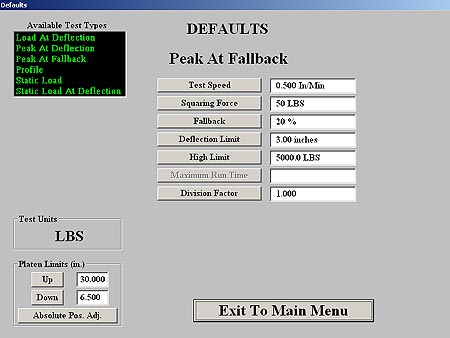

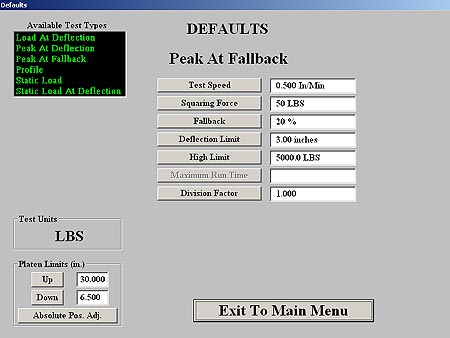

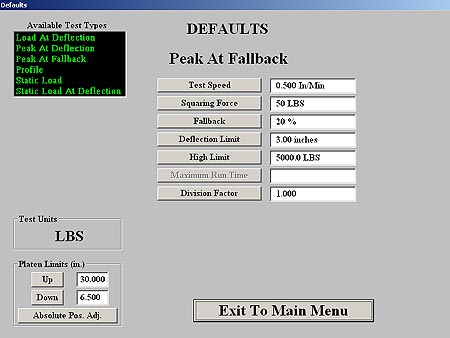

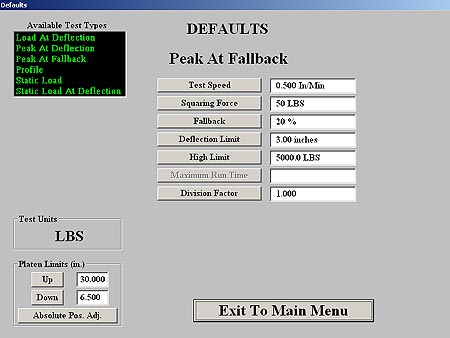

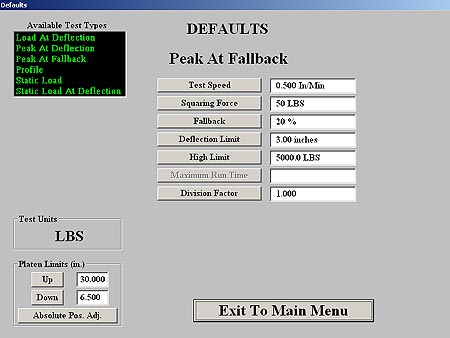

PEAK AT FALLBACK–The “Peak at Fallback” menu lets users select the test type for the current Customer, Product and Test Group; adjust test parameters, adjust product dimensional limits, and compensate for platen opening changes caused by fixtures.

Specifications

- Base Machine: 49″ wide X 69″ high X 32″ deep

- With Operator Station: 79.50″ wide x 68.50″ high x 32″ deep

- Weight: 1,250 lbs max

- Capacity 5,000 lbs

- Platen Size 26″ x 30″

- Platen Opening 28″

- Platen Speed 0 to 5 in/min

- Static Hold Time 0 to 999 hours

- Rupture Sensitivity 0 to 99%

- Preload 0 to 5,000 lbs

- Accuracy .06% of reading or .002% of full scale

- Electrical Single phase 208V/60Hz

Accessories/Options

- Larger platen openings

- Rolling chassis

- Side machine mount option for controller, monitor, printer

Emerson’s Basiloid Tensile & Tape Tensile Fixtures

- Developed for all Model 6200 to 7200 size Emerson Compression Testers

- Tape Tensile Fixture tests the tensile strength of tapes

- Basiloid Tensile Fixture tests the tensile strength of Folding Cap Carton lifting points

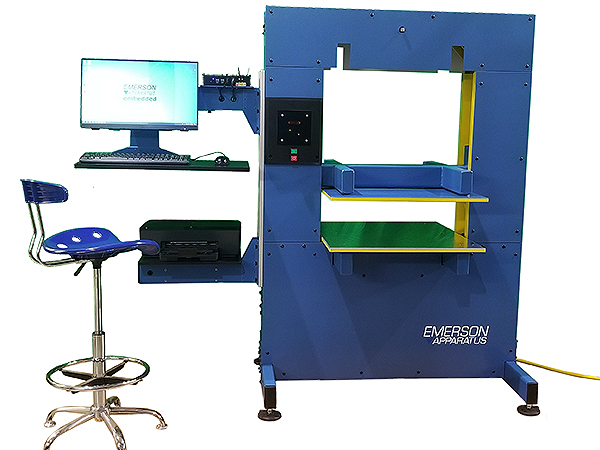

The Emerson Model 6210 Compression Tester was created for the performance testing of shipping containers. Designed in accordance with the requirements of ASTM D642 and TAPPI T804 equipment specifications, its functionality allows for the performance of a variety of test procedures, including T804, D642, D4169, 49 CFR, Item 180, and ISTA.

mounts shown in picture are optional

Features

- Emerson Compression Tester dedicated software package takes full control of the operation of the tester

- Data management is easy with Emerson’s statistical process control (SPC), histograms, and control charts

- Extremely rigid, parallel and flat platens engineered and built for precise yet rugged duty

- Enhanced, dedicated Emerson Compression Tester Software, such as “Test Explorer,” for graphical data allows the user to create unlimited customer box type and identification numbers for products being tested. Also enhanced data management

- Safety features include overload protection, upper & lower limit switches, rapid travel, applied load machine stop

- Software stop limits automatically recalled for the box you are testing

- Industrial Ethernet allows for high speed data transfer, no-loss communications, and inter-system groups

- Comply with ISTA, ASTM, TAPPI and other international and industry recognized standards groups

- Rapid platen return and settable positioning allows for rapid, repetitive testing

- Automatic Tare

- Temperature and humidity module included

- Imperial and Metric capabilities

- Calibrated in accordance with ASTM Method E4

- Standard Language: English

- Easy test value entry boxes, updated error handling, multiple chart overlays, and much more more

- Set maximum and minimum height of the sample and deflection displays at all times

- Enhanced linear motion system rigidity

- Increased platen stiffness

- Maximized dynamic parallelism

- Enhanced shielded machine enclosure

- Reduced equipment footprint

- Integrated adjustable operator workstation

- Enhanced ergonomics: load/unload/operate from same position

- Advanced motion system

- Green high torque motor

- Remote mounted temperature/humidity probe

- Dual plane shielding

- Pluggable electrical panel for turnkey replacements

- Enhanced cable management

- Internal guarding

- Near silent operation

- Adaptable modular frame design

- Solid state industrial controller

- Microsoft Windows 10 Professional

- User WiFi and LAN connections available standard

- 10 point capacitive touch screen

- Complimentary keyboard and mouse tray

- Complimentary stand-up compatible stool

- Caster Kit available (request pricing)

- Test automation option compatible

Software Features/Controller Features

Software Features/Controller Features

All Compression Tester Models come with our Dedicated Computer Controller System, Color Printer, Color Monitor, and our pre-loaded Emerson Compression Tester Software Program (Windows Operating System).

- Dedicated Compression Tester software package

- Windows Operating System

- High-speed computer

- 21″ Flat Panel color display

- Color printer

- Super imposed plotting for viewing multiple test curves

- Program recovery allows the user to recover their Compression Tester software and calibration information

- Enhanced tests have been updated, including a 10-point profile test allowing the user to set up to 10 distinct loads

- Full software support for Compression Tester software versions 5.15 and up

Preview Software

Preview Emerson’s Compression Tester Software which uses familiar Windows-based screens and navigation aids to provide an intuitive and user-friendly interface to your Compression Tester equipment. Data management is easy with our NIST-approved statistical process control (SPC), histograms, and control charts.

Preview +

MAIN MENU–With just a few key strokes, the Compression Tester’s “Main Menu” screen allows users to select test types, run tests, control the compression tester platen, search statistical reports, plot graphs, and/or view graphs on screen.

TEST EXPLORER–With the “Test Explorer” feature, users set up customer box types with specific parameters for each test. Users can also review desired test results and view single plots or superimpose multiple plots on one graph.

PEAK AT FALLBACK–The “Peak at Fallback” menu lets users select the test type for the current Customer, Product and Test Group; adjust test parameters, adjust product dimensional limits, and compensate for platen opening changes caused by fixtures.

Specifications

- Base Machine : 61″ wide X 78.50″ high X 32″ deep

- With Operator Station: 92″ wide x 78.50″ high x 32″ deep

- Weight: 1,550 lbs max

- Capacity 5,000 lbs

- Platen Size 30″ x 38″

- Platen Opening 38″

- Platen Speed 0 to 5 in/min

- Static Hold Time 0 to 999 hours

- Rupture Sensitivity 0 to 99%

- Preload 0 to 5,000 lbs

- Accuracy .06% of reading or .002% of full scale

- Electrical Single phase 208V/60Hz

Accessories/Options

- Larger platen openings

- Rolling chassis

- Side machine mount option for controller, monitor, printer

Emerson’s Basiloid Tensile & Tape Tensile Fixtures

- Developed for all Model 6200 to 7200 size Emerson Compression Testers

- Tape Tensile Fixture tests the tensile strength of tapes

- Basiloid Tensile Fixture tests the tensile strength of Folding Cap Carton lifting points

*dedicated custom factory certified computer controller and software package included, not shown

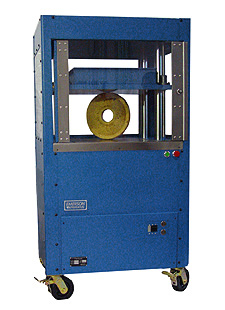

The Emerson Model 5205 Compression Tester was created for the performance testing of roll cores, corrugated shipping containers, tubes, bottles, and cans for the packaging, plastic, and building products industries. It features a protective enclosure to prevent injury from core fragments. Designed in accordance with the requirements of ASTM D642 and TAPPI T804 equipment specifications, its functionality allows for the performance of a variety of test procedures, including T804, D642, D4169, 49 CFR, Item 180, and ISTA.

Features

All Compression Tester Models come with our Dedicated Computer Controller System, Color Printer, Color Monitor, and our pre-loaded Emerson Compression Tester Software Program (Windows Operating System).

- Emerson Compression Tester dedicated software package takes full control of the operation of the tester

- Data management is easy with Emerson’s statistical process control (SPC), histograms, and control charts

- Extremely rigid, parallel and flat platens engineered and built for precise yet rugged duty

- Protective enclosure prevents injury from core fragments

- Four locking extremely heavy duty rotating casters allow this compression tester to be easily moved to different locations for testing

- Ergonomic design reduces operator fatigue

- Four certified load cells

- Four support columns

- Four matched heavy duty ball screws

- Enhanced, dedicated Emerson Compression Tester Software, such as “Test Explorer,” for graphical data allows the user to create unlimited customer box type and identification numbers for products being tested. Also enhanced data management

- Safety features include overload protection, upper & lower limit switches, rapid travel, applied load machine stop, protective enclosure, door kill switch, emergency stop switch

Software stop limits automatically recalled for the box you are testing - Industrial Ethernet allows for high speed data transfer, no-loss communications, and inter-system groups

- Comply with ISTA, ASTM, TAPPI and other international and industry recognized standards groups

- Rapid platen return and settable positioning allows for rapid, repetitive testing

- Automatic Tare

- Temperature and humidity module included

- Imperial and Metric capabilities

- Calibrated in accordance with ASTM Method E4

- Standard Language: English

- Easy test value entry boxes, updated error handling, multiple chart overlays, and much more

- Set maximum and minimum height of the sample and deflection displays at all times

Preview Software

Preview Emerson’s Compression Tester Software which uses familiar Windows-based screens and navigation aids to provide an intuitive and user-friendly interface to your Compression Tester equipment. Data management is easy with our NIST-approved statistical process control (SPC), histograms, and control charts.

Preview +

MAIN MENU–With just a few key strokes, the Compression Tester’s “Main Menu” screen allows users to select test types, run tests, control the compression tester platen, search statistical reports, plot graphs, and/or view graphs on screen.

TEST EXPLORER–With the “Test Explorer” feature, users set up customer box types with specific parameters for each test. Users can also review desired test results and view single plots or superimpose multiple plots on one graph.

PEAK AT FALLBACK–The “Peak at Fallback” menu lets users select the test type for the current Customer, Product and Test Group; adjust test parameters, adjust product dimensional limits, and compensate for platen opening changes caused by fixtures.

Specifications

- Capacity 12,000 LBS

- Platen Size 23″ x 20″

- Platen Opening 22″

- Platen Test Speed 0 to 5 in/min

- Platen Rapid Return Speed 6 in/min

- Static Hold Time 0 to 999 hours

- Rupture Sensitivity 0 to 99%

- Preload 0 to 10,00 LBS

- Accuracy .06% of reading or .002% of full scale

- Resolution 0.5 LBS measured, 0.1 LBS processed

- Dimensions 36″W x 29″D x 67″H

- Weight 1,200 LBS

- Electrical Single/three phase 208V/60Hz

Emerson’s Core Holding Fixture

- Developed for Emerson Compression Tester 5205

- Facilitates core edge crush testing

- Stands cores vertically without interfering with the test results

*dedicated custom factory certified computer controller and software package included, not shown

The Emerson Model 5200 Compression Tester was created for the performance testing of shipping containers. Designed in accordance with the requirements of ASTM D642 and TAPPI T804 equipment specifications, its functionality allows for the performance of a variety of test procedures, including T804, D642, D4169, 49 CFR, Item 180, and ISTA.

Features

All Compression Tester Models come with our Dedicated Computer Controller System, Color Printer, Color Monitor, and our pre-loaded Emerson Compression Tester Software Program (Windows Operating System).

- Emerson Compression Tester dedicated software package takes full control of the operation of the tester

- Data management is easy with Emerson’s statistical process control (SPC), histograms, and control charts

- Extremely rigid, parallel and flat platens engineered and built for precise yet rugged duty

- Four certified load cells

- Four support columns

- Four matched acme power screws

- Enhanced, dedicated Emerson Compression Tester Software, such as “Test Explorer,” for graphical data allows the user to create unlimited customer box type and identification numbers for products being tested. Also enhanced data management

- Safety features include overload protection, upper & lower limit switches, rapid travel, applied load machine stop

- Software stop limits automatically recalled for the box you are testing

- Industrial Ethernet allows for high speed data transfer, no-loss communications, and inter-system groups

- Comply with ISTA, ASTM, TAPPI and other international and industry recognized standards groups

- Rapid platen return and settable positioning allows for rapid, repetitive testing

- Automatic Tare

- Temperature and humidity module included

- Imperial and Metric capabilities

- Calibrated in accordance with ASTM Method E4

- Standard Language: English

- Easy test value entry boxes, updated error handling, multiple chart overlays, and much more

- Set maximum and minimum height of the sample and deflection displays at all times

Preview Software

Preview Emerson’s Compression Tester Software which uses familiar Windows-based screens and navigation aids to provide an intuitive and user-friendly interface to your Compression Tester equipment. Data management is easy with our NIST-approved statistical process control (SPC), histograms, and control charts.

Preview +

MAIN MENU–With just a few key strokes, the Compression Tester’s “Main Menu” screen allows users to select test types, run tests, control the compression tester platen, search statistical reports, plot graphs, and/or view graphs on screen.

TEST EXPLORER–With the “Test Explorer” feature, users set up customer box types with specific parameters for each test. Users can also review desired test results and view single plots or superimpose multiple plots on one graph.

PEAK AT FALLBACK–The “Peak at Fallback” menu lets users select the test type for the current Customer, Product and Test Group; adjust test parameters, adjust product dimensional limits, and compensate for platen opening changes caused by fixtures.

Specifications

- Capacity 10,000 lbs

- Platen Size 40″ x 40″

- Platen Opening 40″

- Platen Speed 0 to 5 in/min

- Static Hold Time 0 to 999 hours

- Rupture Sensitivity 0 to 99%

- Preload 0 to 10,000 lbs

- Accuracy .06% of reading or .002% of full scale

- Height 78″ x width 54″ x depth 42″”

- Weight 1800 lbs

- Electrical 230 VAC, single phase

LVDT Instrument Package (Option)

The LVDT Instrument Package is appropriate for measuring any product displacement when load is applied. The LVDT Instrument Package consists of three (3) linear displacement sensors used on tests that apply loads for prolonged periods where tracking test object sag or other linear displacement measurements are required.

The LVDT Instrument Package is appropriate for measuring any product displacement when load is applied. The LVDT Instrument Package consists of three (3) linear displacement sensors used on tests that apply loads for prolonged periods where tracking test object sag or other linear displacement measurements are required.

Typically used in the pallet testing industry, these sensors are placed vertically under the test item which is set on precision blocks. A load is applied and distributed evenly over the product utilizing a specially designed Emerson load bladder. The force is held on the product and the sag over time is measured under the product at three places. Forces applied may be programmed steps or a single force for a specified duration.

Other tests allow determination of overall load required to meet a specific deflection on the center displacement sensor, with all three sensors charting until conditions are met.

These sensors have a 2” displacement range and are very high resolution (0.0001”).

Additional Accessories/Options

- Larger platen openings

- Rolling chassis

*dedicated custom factory certified computer controller and software package included, not shown

The Emerson Model 5210 Compression Tester was created for the performance testing of shipping containers. Designed in accordance with the requirements of ASTM D642 and TAPPI T804 equipment specifications, its functionality allows for the performance of a variety of test procedures, including T804, D642, D4169, 49 CFR, Item 180, and ISTA.

Features

All Compression Tester Models come with our Dedicated Computer Controller System, Color Printer, Color Monitor, and our pre-loaded Emerson Compression Tester Software Program (Windows Operating System).

- Emerson Compression Tester dedicated software package takes full control of the operation of the tester

- Data management is easy with Emerson’s statistical process control (SPC), histograms, and control charts

- Extremely rigid, parallel and flat platens engineered and built for precise yet rugged duty

- Four certified load cells

- Four support columns

- Four matched acme power screws

- Enhanced, dedicated Emerson Compression Tester Software, such as “Test Explorer,” for graphical data allows the user to create unlimited customer box type and identification numbers for products being tested. Also enhanced data management

- Safety features include overload protection, upper & lower limit switches, rapid travel, applied load machine stop

- Software stop limits automatically recalled for the box you are testing

- Industrial Ethernet allows for high speed data transfer, no-loss communications, and inter-system groups

- Comply with ISTA, ASTM, TAPPI and other international and industry recognized standards groups

- Rapid platen return and settable positioning allows for rapid, repetitive testing

- Automatic Tare

- Temperature and humidity module included

- Imperial and Metric capabilities

- Calibrated in accordance with ASTM Method E4

- Standard Language: English

- Easy test value entry boxes, updated error handling, multiple chart overlays, and much more

- Set maximum and minimum height of the sample and deflection displays at all times

Preview Software

Preview Emerson’s Compression Tester Software which uses familiar Windows-based screens and navigation aids to provide an intuitive and user-friendly interface to your Compression Tester equipment. Data management is easy with our NIST-approved statistical process control (SPC), histograms, and control charts.

Preview +

MAIN MENU–With just a few key strokes, the Compression Tester’s “Main Menu” screen allows users to select test types, run tests, control the compression tester platen, search statistical reports, plot graphs, and/or view graphs on screen.

TEST EXPLORER–With the “Test Explorer” feature, users set up customer box types with specific parameters for each test. Users can also review desired test results and view single plots or superimpose multiple plots on one graph.

PEAK AT FALLBACK–The “Peak at Fallback” menu lets users select the test type for the current Customer, Product and Test Group; adjust test parameters, adjust product dimensional limits, and compensate for platen opening changes caused by fixtures.

Specifications

- Capacity 10,000 lbs

- Platen Size 40″ x 48″

- Platen Opening 48″

- Platen Speed 0 to 5 in/min

- Static Hold Time 0 to 999 hours

- Rupture Sensitivity 0 to 99%

- Preload 0 to 10,000 lbs

- Accuracy .06% of reading or .002% of full scale

- Dimensions 82″ x 98″ x 50″

- Weight 2500 lbs

- Electrical 230 VAC, single phase

LVDT Instrument Package (Option)

The LVDT Instrument Package is appropriate for measuring any product displacement when load is applied. The LVDT Instrument Package consists of three (3) linear displacement sensors used on tests that apply loads for prolonged periods where tracking test object sag or other linear displacement measurements are required.

The LVDT Instrument Package is appropriate for measuring any product displacement when load is applied. The LVDT Instrument Package consists of three (3) linear displacement sensors used on tests that apply loads for prolonged periods where tracking test object sag or other linear displacement measurements are required.

Typically used in the pallet testing industry, these sensors are placed vertically under the test item which is set on precision blocks. A load is applied and distributed evenly over the product utilizing a specially designed Emerson load bladder. The force is held on the product and the sag over time is measured under the product at three places. Forces applied may be programmed steps or a single force for a specified duration.

Other tests allow determination of overall load required to meet a specific deflection on the center displacement sensor, with all three sensors charting until conditions are met.

These sensors have a 2” displacement range and are very high resolution (0.0001”).

Additional Accessories/Options

- Larger platen openings

- Rolling chassis

*dedicated custom factory certified computer controller and software package included, not shown

The Emerson Model 7200 Compression Tester was created for the performance testing of shipping containers. Designed in accordance with the requirements of ASTM D642 and TAPPI T804 equipment specifications, its functionality allows for the performance of a variety of test procedures, including T804, D642, D4169, 49 CFR, Item 180, and ISTA.

Features

- Emerson Compression Tester dedicated software package takes full control of the operation of the tester

- Data management is easy with Emerson’s statistical process control (SPC), histograms, and control charts

- Extremely rigid, parallel and flat platens engineered and built for precise yet rugged duty

- Four certified load cells

- Four support columns

- Four matched acme power screws

- Enhanced, dedicated Emerson Compression Tester Software, such as “Test Explorer,” for graphical data allows the user to create unlimited customer box type and identification numbers for products being tested. Also enhanced data management

- Safety features include overload protection, upper & lower limit switches, rapid travel, applied load machine stop

- Software stop limits automatically recalled for the box you are testing

- Industrial Ethernet allows for high speed data transfer, no-loss communications, and inter-system groups

- Comply with ISTA, ASTM, TAPPI and other international and industry recognized standards groups

- Rapid platen return and settable positioning allows for rapid, repetitive testing

- Automatic Tare

- Temperature and humidity module included

- Imperial and Metric capabilities

- Calibrated in accordance with ASTM Method E4

- Standard Language: English

- Easy test value entry boxes, updated error handling, multiple chart overlays, and much more

- Set maximum and minimum height of the sample and deflection displays at all times

Software Features/Controller Features

All Compression Tester Models come with our Dedicated Computer Controller System, Color Printer, Color Monitor, and our pre-loaded Emerson Compression Tester Software Program (Windows Operating System).

- Dedicated Compression Tester software package

- Windows Operating System

- High-speed computer

- 21″ Flat Panel color display

- Color printer

- Super imposed plotting for viewing multiple test curves

- Program recovery allows the user to recover their Compression Tester software and calibration information

- Enhanced tests have been updated, including a 10-point profile test allowing the user to set up to 10 distinct loads

- Full software support for Compression Tester software versions 5.15 and up

Preview Software

Preview Emerson’s Compression Tester Software which uses familiar Windows-based screens and navigation aids to provide an intuitive and user-friendly interface to your Compression Tester equipment. Data management is easy with our NIST-approved statistical process control (SPC), histograms, and control charts.

Preview +

MAIN MENU–With just a few key strokes, the Compression Tester’s “Main Menu” screen allows users to select test types, run tests, control the compression tester platen, search statistical reports, plot graphs, and/or view graphs on screen.

TEST EXPLORER–With the “Test Explorer” feature, users set up customer box types with specific parameters for each test. Users can also review desired test results and view single plots or superimpose multiple plots on one graph.

PEAK AT FALLBACK–The “Peak at Fallback” menu lets users select the test type for the current Customer, Product and Test Group; adjust test parameters, adjust product dimensional limits, and compensate for platen opening changes caused by fixtures.

Specifications

- Capacity 20,000 lbs

- Platen Size 48″ x 48″

- Platen Opening 48″

- Platen Speed 0 to 5 in/min

- Static Hold Time 0 to 999 hours

- Rupture Sensitivity 0 to 99%

- Preload 0 to 20,000 lbs

- Accuracy .06% of reading or .002% of full scale

- Dimensions 85″ x 99″ x 50″

- Weight 5300 lbs

- Electrical Single/three phase 208V/60Hz

LVDT Instrument Package (Option)

The LVDT Instrument Package is appropriate for measuring any product displacement when load is applied. The LVDT Instrument Package consists of three (3) linear displacement sensors used on tests that apply loads for prolonged periods where tracking test object sag or other linear displacement measurements are required.

The LVDT Instrument Package is appropriate for measuring any product displacement when load is applied. The LVDT Instrument Package consists of three (3) linear displacement sensors used on tests that apply loads for prolonged periods where tracking test object sag or other linear displacement measurements are required.

Typically used in the pallet testing industry, these sensors are placed vertically under the test item which is set on precision blocks. A load is applied and distributed evenly over the product utilizing a specially designed Emerson load bladder. The force is held on the product and the sag over time is measured under the product at three places. Forces applied may be programmed steps or a single force for a specified duration.

Other tests allow determination of overall load required to meet a specific deflection on the center displacement sensor, with all three sensors charting until conditions are met.

These sensors have a 2” displacement range and are very high resolution (0.0001”).

Additional Accessories/Options

- Larger platen openings

- Rolling chassis

Emerson’s Basiloid Tensile & Tape Tensile Fixtures

- Developed for all Model 6200 to 7200 size Emerson Compression Testers

- Tape Tensile Fixture tests the tensile strength of tapes

- Basiloid Tensile Fixture tests the tensile strength of Folding Cap Carton lifting points

*dedicated custom factory certified computer controller and software package included, not shown

**picture shown is custom platen size 60″ x 100″ (standard model platen size is 60″ x 60″)

The Emerson Model 8510 Compression Tester was created for the performance testing of shipping containers. Designed in accordance with the requirements of ASTM D642 and TAPPI T804 equipment specifications, its functionality allows for the performance of a variety of test procedures, including T804, D642, D4169, 49 CFR, Item 180, and ISTA.

Features

Picture shown is Custom platen size 60″ x 100″

Standard Model 8510 platen size is 60″ x 60″

- Emerson Compression Tester dedicated software package takes full control of the operation of the tester

- Data management is easy with Emerson’s statistical process control (SPC), histograms, and control charts

- Extremely rigid, parallel and flat platens engineered and built for precise yet rugged duty

- Four certified load cells

- Four support columns

- Four matched acme power screws

- Enhanced, dedicated Emerson Compression Tester Software, such as “Test Explorer,” for graphical data allows the user to create unlimited customer box type and identification numbers for products being tested. Also enhanced data management

- Safety features include overload protection, upper & lower limit switches, rapid travel, applied load machine stop

- Software stop limits automatically recalled for the box you are testing

- Industrial Ethernet allows for high speed data transfer, no-loss communications, and inter-system groups

- Comply with ISTA, ASTM, TAPPI and other international and industry recognized standards groups

- Rapid platen return and settable positioning allows for rapid, repetitive testing

- Automatic Tare

- Temperature and humidity module included

- Imperial and Metric capabilities

- Calibrated in accordance with ASTM Method E4

- Standard Language: English

- Easy test value entry boxes, updated error handling, multiple chart overlays, and much more

- Set maximum and minimum height of the sample and deflection displays at all times

Software Features/Controller Features

All Compression Tester Models come with our Dedicated Computer Controller System, Color Printer, Color Monitor, and our pre-loaded Emerson Compression Tester Software Program (Windows Operating System).

- Dedicated Compression Tester software package

- Windows Operating System

- high-speed computer

- 21″ Flat Panel color display

- Color printer

- Super imposed plotting for viewing multiple test curves

- Program recovery allows the user to recover their Compression Tester software and calibration information

- Enhanced tests have been updated, including a 10-point profile test allowing the user to set up to 10 distinct loads

- Full software support for Compression Tester software versions 5.15 and up

Preview Software

Preview Emerson’s Compression Tester Software which uses familiar Windows-based screens and navigation aids to provide an intuitive and user-friendly interface to your Compression Tester equipment. Data management is easy with our NIST-approved statistical process control (SPC), histograms, and control charts.

Preview +

MAIN MENU–With just a few key strokes, the Compression Tester’s “Main Menu” screen allows users to select test types, run tests, control the compression tester platen, search statistical reports, plot graphs, and/or view graphs on screen.

TEST EXPLORER–With the “Test Explorer” feature, users set up customer box types with specific parameters for each test. Users can also review desired test results and view single plots or superimpose multiple plots on one graph.

PEAK AT FALLBACK–The “Peak at Fallback” menu lets users select the test type for the current Customer, Product and Test Group; adjust test parameters, adjust product dimensional limits, and compensate for platen opening changes caused by fixtures.

Specifications

- Capacity 45,000 lbs

- Platen Type Fixed/Floating

- Platen Size 60″ x 60″

- Platen Opening 96″

- Platen Speed 0 to 5 in/min

- Static Hold Time 0 to 999 hours

- Rupture Sensitivity 0 to 99%

- Preload 0 to 45,000 lbs

- Accuracy .06% of reading or .002% of full scale

- Dimensions 80″ x 74″ x 130″

- Weight 12,450 lbs

- Electrical Three phase 220V/60Hz

Accessories/Options

- Rolling Test Tables available for small box testing requirements

- Floor Loading Access

Pictured: Modified 2210 Compression Tester.

If you have a specific testing or sample size requirement, Emerson Apparatus can customize any of its Compression Testers (from Model 2210 to Model 8510) to meet your platen size and platen opening requirements, as well as custom software and testing needs.

For example, in this modified 2210 compression tester (see picture), Emerson Apparatus designed and manufactured a 2,000-pound tester with a 13″ wide x 20″ deep x 16″ platen. It has all the capabilities of our standard Model 2210, but with a larger test area.

Emerson Apparatus engineers are experts at working with customers to design custom solutions for you. Contact us today to discuss your specific needs.

Contact Us

Email

sales@emersonapparatus.com

Phone*

IDD 1-207-856-0055

Business Hours

Monday through Friday, 8:00 a.m. to 4:30 p.m. (Eastern Time)

*Where IDD is your international dialing prefix as may be required when making international calls to the United States.

Emerson Apparatus can customize any of our Compression Testers to meet your specific size requirements and software/testing needs (pictured: modified 2210 Compression Tester). MORE +

Emerson Apparatus can customize any of our Compression Testers to meet your specific size requirements and software/testing needs (pictured: modified 2210 Compression Tester). MORE +

Emerson’s compression tester electronics & software upgrade brings your older machine to current technology with all new electronics and software running Windows embedded Operating System. For Emerson Compression Tester models 6200, 6210, 5200, 5210, 7200, and 8510. MORE +

Faster platen return speed, software enhancements, and heavy duty power-train. Available for newer/previously upgraded Emerson Compression Tester Models 6200, 6210, 5200, 5205, 5210 & 7200. Customers with older Emerson Compression Testers, can upgrade their testers first with our compression tester electronics & software upgrade package. MORE +

Faster platen return speed, software enhancements, and heavy duty power-train. Available for newer/previously upgraded Emerson Compression Tester Models 6200, 6210, 5200, 5205, 5210 & 7200. Customers with older Emerson Compression Testers, can upgrade their testers first with our compression tester electronics & software upgrade package. MORE +