info@emersonapparatus.com

Shaker Peripherals designs can range from a very simple Head or Slip plates with a few attachment holes to complex devices with automatic features to enhance production testing with quick insertion and/or removal of production test items. To discuss your peripheral needs, contact Emerson Apparatus today or use our Get a Quote feature. We’ll be glad to discuss a solution that’s right for you.

Options

Optional features include damping treatment, corrosion protection, thermal barrier, thermal treatment, shaker guidance/support and a choice of insert locations. Other standard fixtures are available for mounting product to the shaker, such as cubes, L fixtures and T fixtures. These fixtures provide a means to position the test specimen to allow for multi-axis testing without rotating the shaker head from the vertical to horizontal position.

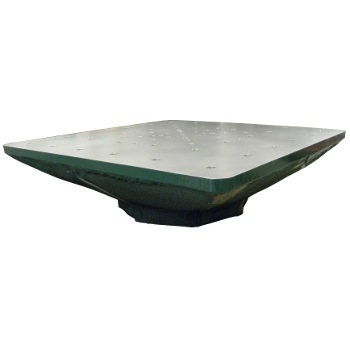

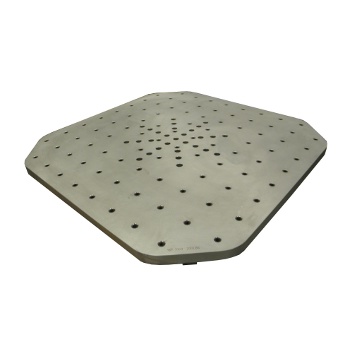

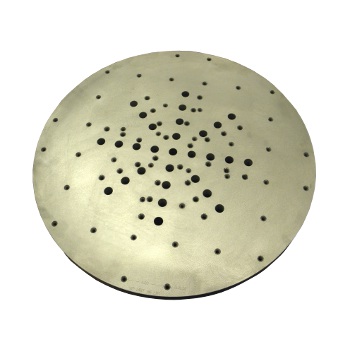

Head Expanders provide a larger surface to attach test specimens. Most head expanders are fabricated from magnesium to provide the optimum combination of light weight, rigidity and strength. They are available in round, square or rectangular shapes. Smaller head expanders are typically machined from a solid while larger ones are manufactured as a weldment. In some cases it may be more cost effective to utilize a casting for extremely large head expanders.

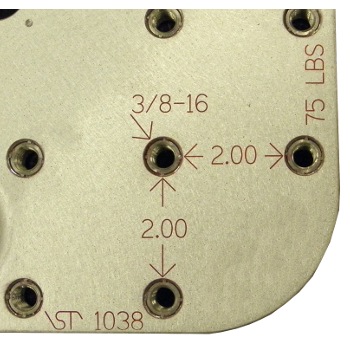

Rarely are any two Head Expander requirements the same. VST Designs each Head Expander to satify each customer’s specs. The working surface size, bolt pattern, shaker pattern, armature diameter and weight are all factors that determine what the first resonant frequency will be. FEA analysis is used to identify the modes and resonant frequencies in SolidWorks prior to final approval and construction. VST engraves the bolt pattern dimensions right on the work surface so there wil be no questions about which bolt pattern(s) it has.

Options

Load Support

Air Springs are used to neutralize the load on the shaker flexures by supporting the addtional weight of the Head Expander and payload.

Linear Guidance

Often utilized with load support, Linear Guidance provides lateral support and reduces any side loads or overturning moments that would exceed the limits of the shaker armature guidance.

Thermal Barrier

Head Expanders can be supplied with a Thermal Barrier made of G-10 or SG-200 for use in thermal chambers to reduce the amount of thermal transfer.

Corrosion Protection

An untreated Head Expander will last for years and years, however they will oxidize over time. When they’re used in thermal chambers condensation can accelerate the process. Powder coating is a good option for applications below 300°F. HAE can be used for higher temperature requirements.

Damping Treatment

Accomplished using AB foam or linear damping material, damping treament can help reduce the Q or amplification factor at the resonant frequency of the Head Expander / shaker system. Damping treatment is not as effective as a properly designed Head Expander, but it can help the controllability at or near resonant frequencies.