SUPPORT GET QUOTE

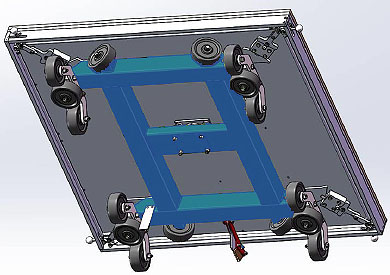

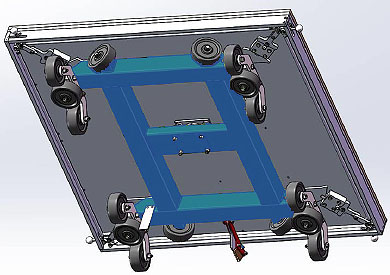

With Emerson Incline Impact Testers, a massive steel framework faced with group 4 wood or steel serves as an impact surface. A hydraulic lift mechanism positions the angle of the rail assembly, while a Lazy-Susan Carriage aids re-orientation of the unit under test.

Incline Tester Lazy-Susan Carriage

Features

- Up to 10,000 lbs. capacity – more for custom applications

- Custom carriages and backstops

- Lazy-Susan carriage and rails that raise and lower for more efficient unit loading, reorientation, and test through-put

- Laser-velocity sensor data acquisition for displaying impact and rebound velocities and total velocity change

- In-house, self-calibration of laser-velocity sensor

- Optional: Rails can fold up to regain floor space

Emerson Apparatus Incline Impact Tester

Models & Specs

| Payload Capacity |

1,000 lbs |

2,000 lbs |

4,000 lbs |

6,000 lbs |

8,000 lbs |

10,000 lbs |

| Impact Wall |

60 in x 60 in |

72 in x 72 in |

84 in x 84 in |

84 in x 84 in |

84 in x 84 in |

96 in x 96 in |

| Table Surface Area |

48 in x 48 in |

60 in x 60 in |

72 in x 72 in |

72 in x 72 in |

72 in x 72 in |

84 in x 84 in |

| Impact Velocity |

8 ft/sec |

8 ft/sec |

8 ft/sec |

8 ft/sec |

8 ft/sec |

8 ft/sec |

| Simulates Free Fall Height |

18 in |

18 in |

18 in |

18 in |

18 in |

18 in |

Customization

- Custom capacities, table sizes, backstops, carriages, and paint jobs are available.

Requirements

- Power Requirements: 208-240 <20 Amps single phase

- PC needs separate power supply.

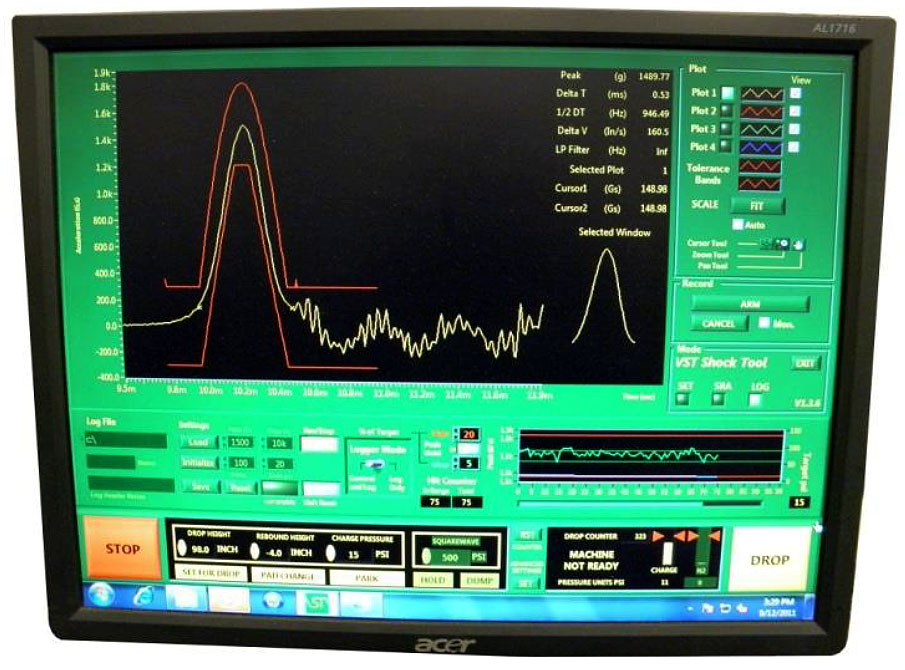

Software & Controls

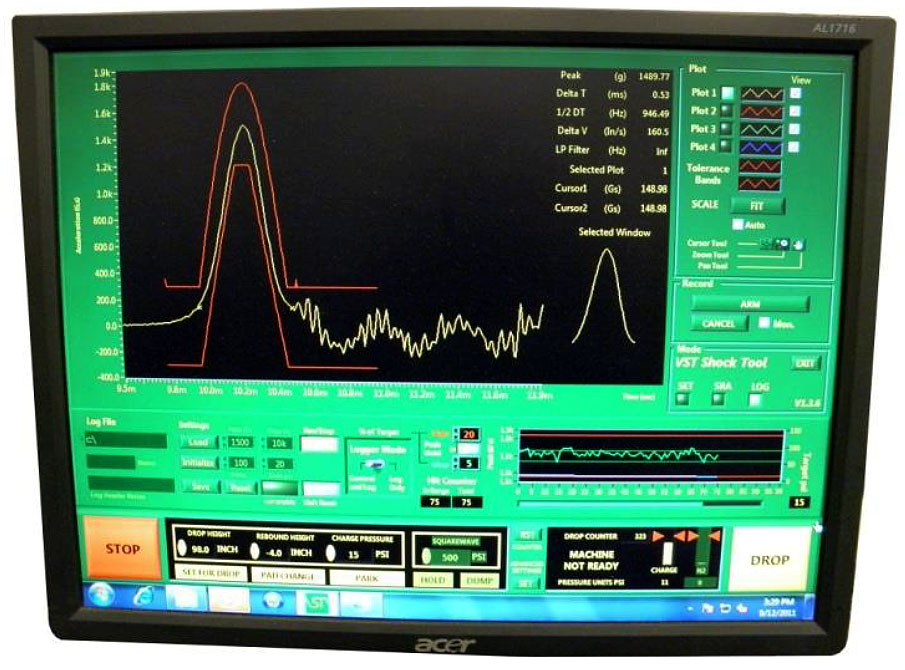

Emerson Incline Impact Testers come with Windows-based PC Acquisition Software, PC, and Emerson velocity laser sensor. The software provides a digital readout of distance to a target mounted on the carriage. Upon release of the carriage, the laser measures the rate the distance was travelled and provides a velocity read out. On set up, the laser provides expected velocity based on distance to the carriage target and incline angle of the rails. This gives users a better idea of starting point and undertesting potential. If the desired velocity is not met, the software provides users with a new release distance setpoint to start from.

Emerson Incline Impact Tester Software Screen

Emerson Apparatus PC Controller

PC Controller and Software is provided for:

- System on/off

- Drop Angle

- Release and Return

- Cycle Count

- Expected Data Calculation

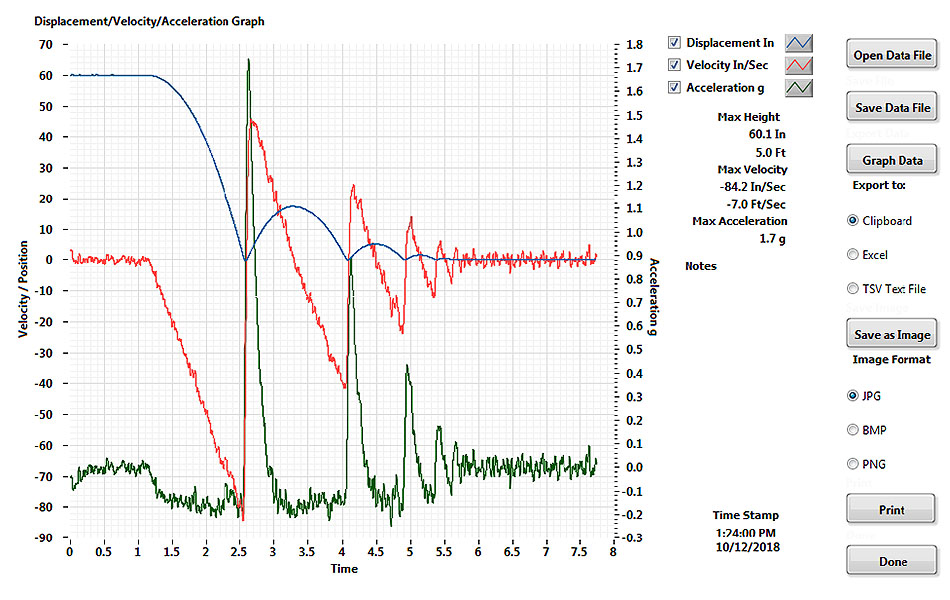

Realtime Data Acquisition

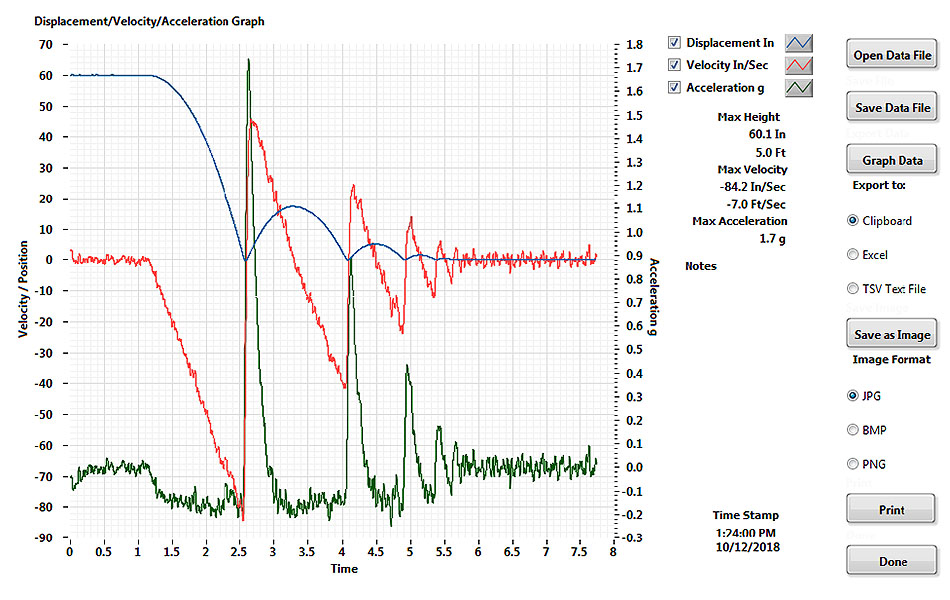

Emerson utilizes its proven data acquisition system to give users the ability to better understand what’s happening to the product under test vs. a simple pass/fail.

Emerson Incline Tester Displacement-Velocity-Acceleration Graph

For example, the Displacement/Velocity/Acceleration Graph “Live View” displays current data on the right side of the screen, and a time history of the last 10 seconds on the left. (This view is for reference only and not used for Velocity or Acceleration measurements. Velocity is derived from the position data and Acceleration is derived from the velocity data.)

In-House Calibration

Users can save time and money by being able to quickly verify the output of the Emerson Laser Velocity Sensor in-house. There’s no need to send back to the manufacturer or to a third-party calibration house. The Emerson calibration process utilizes verification of distance at certain laser voltage readings, utilizing a standard tape measure.

What’s the Right Tester for You?

To discuss your Incline Impact Tester needs, contact Emerson Apparatus today or use our Get a Quote feature. We’ll be glad to discuss a solution that’s right for you, including a custom tester.