info@emersonapparatus.com

Providing the Highest Quality for Decades

(For a larger view, click on the image of each speed dryer)

Using the Emerson Speed Dryer and a direct reading basis weight scale, an accurate percent moisture determination can be made on an average sheet in less than five minutes to tear-out of final weight. With a 230°C option, the speed dryer is being used more and more to test the moisture content of non-woven fiber materials.

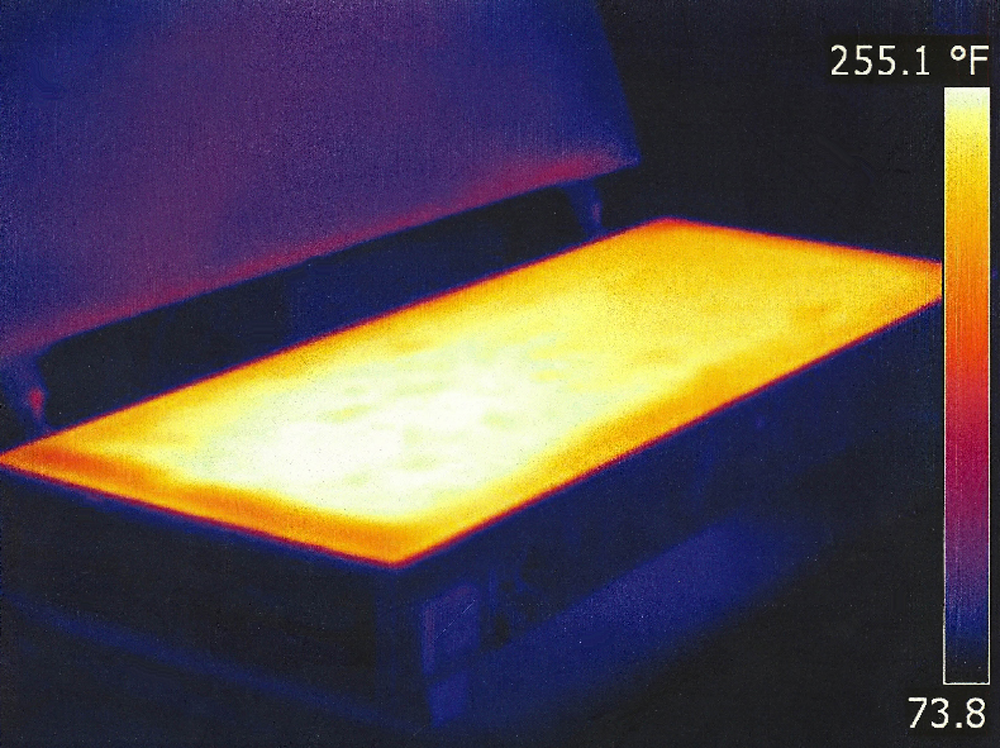

Image shows uniformity of the heat distribution across working surface of Emerson Speed Dryer

Precision Temperature Control

There are many tests that require precision control of the sample drying temperatures. For example: TAPPI T412 Moisture in pulp, paper, and paperboard test specification requires 221 ± 3.6ºF to be applied to the sample for 60 ± 5 minutes. Testing compliancy cannot be claimed when deviating from specified testing standards and procedures. Our speed dryer also supports similar standards for ISO, CPPA, ASTM and APPITA for pulp, paper, and fiber testing.

Features

- Regularly used with the applicable TAPPI, CPPA, ASTM and APPITA test methods

- New dielectric distributed heat plate provides stable linear heat source for drying samples

- New tight PID thermal control of the heat plate allows desired temperatures to be reached fast and accurately regardless of varying load conditions

- New multilayer ceramic insulation maintains extremely high heat source efficiency

- New non-conductive cover handle eliminates the transfer of heat and is now cool to the touch

- Our heavy vented cover, hinged at the rear, is fitted with a non-asbestos breathable fabric cover pad that functions as a dryer felt and presses the sample or hand sheet firmly against the flat, heated plate

- Digital set point controller and heavy duty solid state relay provide reliable long life control

- Ruggedly built and constructed for continuous service in pulp and paper mill laboratories and other industrial testing environments

Specifications

- Control accuracy ±1°C at 105°C

- Range to 150°C (230°C available on request)

- Plate area 14″ X 24″

- Enhanced surface temperature linearity +/- 2.5 degree C of the entire plate and <+/- 0.1 degree C/cm variation (except perimeter)

- Voltage 110VAC or 220VAC (specify)

- 1000 Watts

- Weight 45 lbs

- Shipping dimensions 30″ x 9″ x 20″

Accessories/Options

- 230°C option allows for test preparation of non-woven fiber materials

- Direct reading basis weight scale

Using the Emerson Speed Dryer and a direct reading basis weight scale, an accurate percent moisture determination can be made on an average sheet in less than five minutes to tear-out of final weight. With a 230°C option, the speed dryer is being used more and more to test the moisture content of non-woven fiber materials.

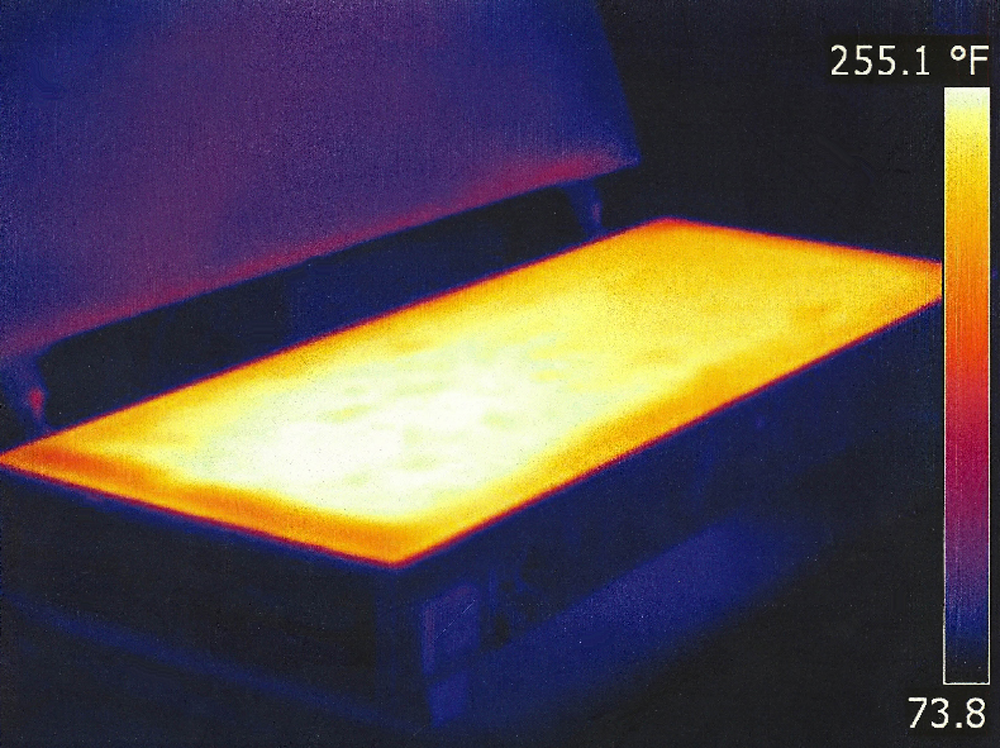

Image shows uniformity of the heat distribution across working surface of Emerson Speed Dryer

Precision Temperature Control

There are many tests that require precision control of the sample drying temperatures. For example: TAPPI T412 Moisture in pulp, paper, and paperboard test specification requires 221 ± 3.6ºF to be applied to the sample for 60 ± 5 minutes. Testing compliancy cannot be claimed when deviating from specified testing standards and procedures. Our speed dryer also supports similar standards for ISO, CPPA, ASTM and APPITA for pulp, paper, and fiber testing.

Features

- Regularly used with the applicable TAPPI, CPPA, ASTM and APPITA test methods

- New dielectric distributed heat plate provides stable linear heat source for drying samples

- New tight PID thermal control of the heat plate allows desired temperatures to be reached fast and accurately regardless of varying load conditions

- New multilayer ceramic insulation maintains extremely high heat source efficiency

- New non-conductive cover handle eliminates the transfer of heat and is now cool to the touch

- Our heavy vented cover, hinged at the rear, is fitted with a non-asbestos breathable fabric cover pad that functions as a dryer felt and presses the sample or hand sheet firmly against the flat, heated plate

- Digital set point controller and heavy duty solid state relay provide reliable long life control

- Ruggedly built and constructed for continuous service in pulp and paper mill laboratories and other industrial testing environments

- Larger plate area than Model 140

Specifications

- Control accuracy ±1°C at 105°C

- Range to 150°C (230°C available on request)

- Plate area 14″ X 36″

- Enhanced surface temperature linearity +/- 2.5 degree C of the entire plate and <+/- 0.1 degree C/cm variation (except perimeter)

- Voltage 110VAC or 220VAC (specify)

- 1500 Watts

- Weight 65 lbs

- Shipping dimensions 42″ x 9″ x 20″

Accessories/Options

- 230°C option allows for test preparation of non-woven fiber materials

- Direct reading basis weight scale