info@emersonapparatus.com

(For a larger view, click on the image of each test fixture.)

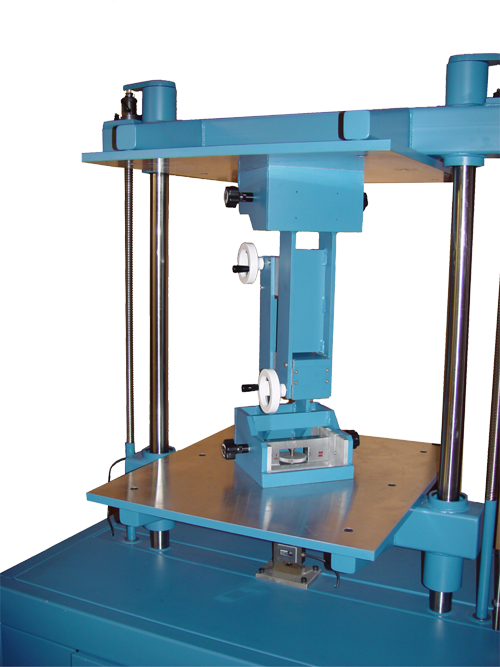

Emerson leads the way with our acclaimed ECT Holding Fixture, which utilizes the mechanical clamping method referenced in TAPPI Test Method T 839. The clamp method produces consistently higher results than the wax method, with ECT values equal to or better than the wax method and without the variability often associated with it.

Why choose Emerson’s ECT Fixture?

The Emerson ECT fixture IS the industry standard directly referenced in TAPPI specifications. Custom alloys, proprietary production equipment, heat and chemical hardness treating, specialized manufacturing procedures, highest precision long-life components, per-piece quality assurance, after-market user calibration capability, and decades of experience working with standards organizations as well as end users allow us to offer the quality and reliability that the industrial testing industry needs and expects.

Features

- No waxing

- No neckdown cutters

- One sample size for all board

- Repeatable results

- Less operator influence

- Yields low standard deviation

- Easy Operation

Specifications

- Sample Size 2″ X 2″

- TAPPI Test T839 OM12

- Shipping Dimensions 10″ X 3″ X 7″

- Shipping Weight 6 lbs

Accessories/Options

Emerson Certified ECT Calibration & Maintenance Kit

- Required to re-calibrate the parallelism of Emerson’s ECT Fixture

- Required for maintenance on the friction paper on the ECT Fixture

- Confirm calibration on site

- Easy to use

Kit Includes:

Parallelizing Block

(2) Adjustment tools

Precision Work Surface Plate

Replacement Friction Paper (4 pieces)

Instruction Manual

ECT Calibration & Maintenance Kit Instructional Video

See Also

Model 1210 Crush Tester +

Model 2210 Compression Tester +

Sample Cutters +

ECT PDF One-sheet +

Emerson’s NEW ECT Fixture Upgrade/Refurbish Kit replaces the upper body of the Emerson Apparatus ECT Test Fixture mechanism. This includes the spring retainer body, the spring retainer end, spindle, knob, spring, and platen.

- The new body mechanism contains a tapered end that allows the knob to go up inside of it to lock it in.

- This prevents accidental overtightening by the user and crushing the sample before testing.

- ECT Fixtures 15 years or older were designed without the taper. Over time, the springs may have worn a little and no longer give the pressure they once did to hold the sample.

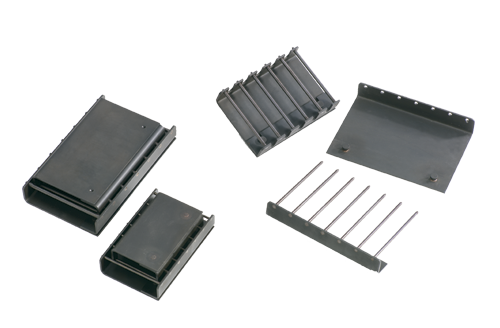

Emerson’s ECT Calibration & Maintenance Kit consists of a precision 1/4″ x 2″ x 2″ calibrated parallel block and tools used for periodic parallelism confirmation for Emerson’s ECT Fixture.

- Required to re-calibrate the parallelism of ECT Fixture and for maintenance on the friction paper on the ECT Fixture

- Confirm calibration of your testing fixture on site

- Easy-to-use

Kit Includes:

- Parallelizing Block

- (2) Adjustment tools

- Precision Work Surface Plate

- Replacement Friction Paper (4 pieces)

- Instruction Manual

ECT Calibration & Maintenance Kit Instructional Video

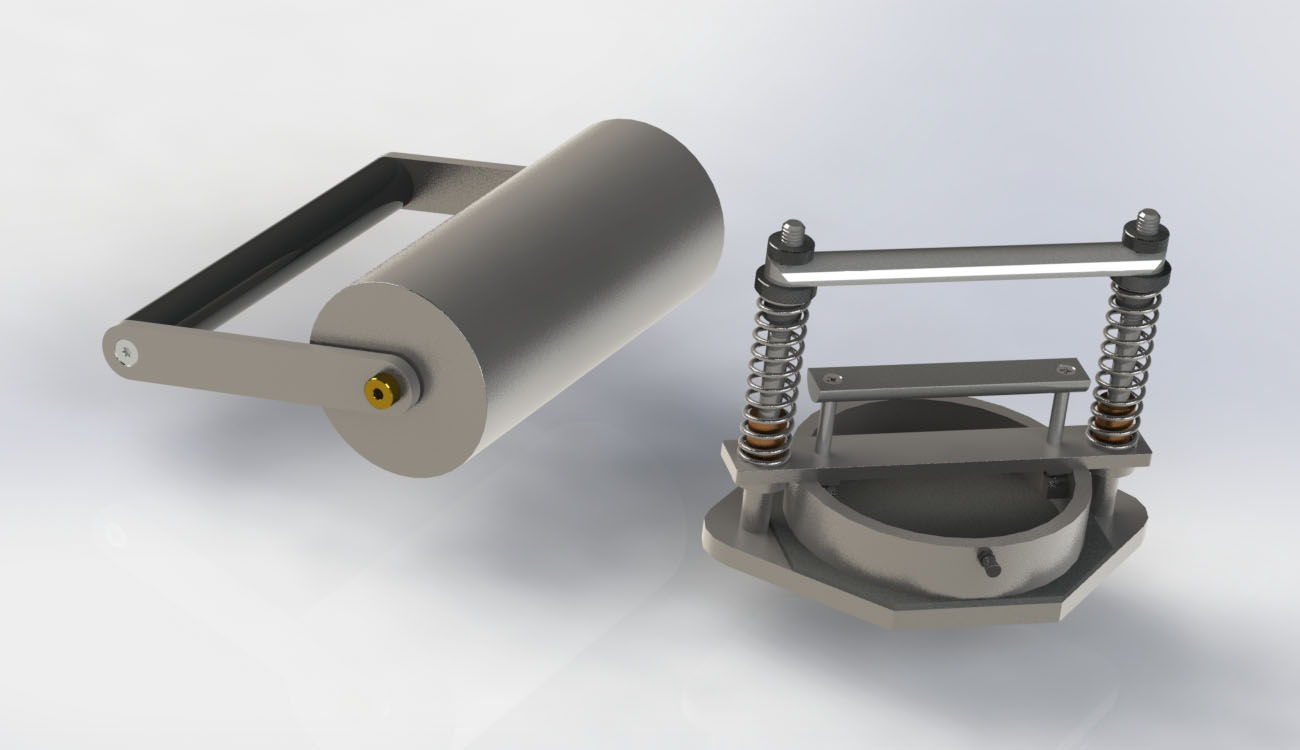

Emerson Ring Crush Fixtures utilize precision disk sets to cover calipers from <.0050″ to >.0390″ as prescribed in TAPPI Test Methods T-818 and T-822. A full range of paper calipers from <.0050″ to >.0390″ can be handled using the 12-disc Set.

Features

- Precision Disk Sets to cover calipers from <.0050″ to >.0390″ as prescribed in TAPPI Test Method T-818 and T-822

- Hardened steel posts and bushings maintain fixture concentricity for life

- Mounting block stores entire set

Specifications

- 12-piece set for calipers <.0050″ to >.0390″

- Precision Sample Cutter 1/2″ x 6″ also available

See Also

Features

- Determine the characteristics and strength of bond formed during the corrugating operation

- Select-side and weak-side pin adhesion fixtures designed for ease of assembly with test sample

- Custom pin spacing, as well as double-wall fixtures, made to order

- TAPPI T-821 (Selective)

- A, B, C Flute Fixtures available

- Non-selective Fixtures

- Custom Fixtures

Emerson’s Core Holding Fixture is designed to facilitate core edge crush testing without interfering with test results by assisting the core to stand vertically before testing begins. Prevents core from kicking out of the fixture, which could cause an unsafe condition of ejected debris. For use with Emerson Compression Tester Model 5205.

Features

- Designed to facilitate core edge crush testing

- Used with Emerson Compression Tester Model 5205

- Stands cores vertically without interfering with the test results

- Prevents the core from kicking out of the fixture, which could cause unsafe conditions

- Tests 3″ through 5″ cores (using an adapter block) as well as 6″ and higher core sizes

See Also

Emerson’s Basiloid Tensile Fixture was developed for all Model 6200 to 7200 size Emerson Compression Testers to test the tensile strength of Folding Cap Carton lifting points using the compressive force of your Emerson Compression Tester.

Features

- Easy installation using the Emerson quick-connect mount points

- High force basiloid clamps allow basiloid samples to be easily installed and held securely throughout this high force destructive test

- Easy test setup using standard test parameters and simple settings to ensure easy and safe operation

- Test settings may be saved and retrieved for convenient and fast selection of test parameters

- Fixture design allows easy insertion and removal of the sample for faster testing

- Easy fixture removal allows you to return quickly to normal compression testing duties with your Emerson compression tester

- Fixture can be oriented side-to-side, front-to-back, or at a 45° angle per operator preference and to accommodate platen size

Emerson’s Tape Tensile Fixture was developed for all Model 6200 to 7200 size Emerson Compression Testers to test the tensile strength of tapes using the compressive force of your Emerson Compression Tester.

Features

- Easy installation using the Emerson quick-connect mount points

- High force tape clamp jaws allow tape samples to be easily installed and securely held WITHOUT patterned surfaces that could reduce the tape strength for testing

- Easy test setup using standard test parameters and simple settings to ensure easy and safe operation

- Test settings may be saved and retrieved for convenient and fast selection of test parameters

- Fixture design allows easy insertion and removal of the sample for faster testing

- Easy fixture removal allows you to return quickly to normal compression testing duties with your Emerson Compression Tester