info@emersonapparatus.com

(For a larger view, click on the image of each crush tester)

Emerson’s newly-redesigned Model 1210 Crush Tester is a robust, rigid support, single column type compression tester designed to determine the compressive strength of various material samples for many industries. The Model 1210 offers fixed parameter tests to perform standardized TAPPI testing including ECT, PAT, FCT, RCT, CMT, and CFC. The machine includes a high-speed on-board computer with a color, touch-screen, flat panel monitor.

Compressive force is provided by two rigid platens. The bottom platen is driven and the top platen rests on four certified load cells to guarantee the most accurate test results. The Model 1210 quickly and reliably captures test results, stores data and groups it for statistical analysis and allows averaging, standard deviation, histograms, and control charts.

NEW Features & Improvements

- TOUCH SCREEN: Run your machine via touch buttons on-screen with the new, nearly-flush display.

- RECESSED CONSOLE: Shielded from glare and recessed for protection, the heavy-duty console is more at home in industrial production environments.

- WHISPER QUIET: New noise dampening enclosure reduces machine operation noise to near-inaudible levels, perfect for the lab.

- DOUBLE SHIELDING: Enclosure panels incorporate embedded dual-plane RFI shielding for advanced noise immunity.

- ENHANCED G-SHOCK CAPABILITY: New electronic layouts with enhanced support, plus increased enclosure mechanical strength, allow this unit to survive greater G-Shock during moving or shipping.

- INCREASED STAGING AREA: The top of the Model 1210 has been maximized to allow more area for test staging.

- VIBRATION RESISTANCE: A greatly increased base mass increases external vibration resistance of test mechanisms.

- CONSOLIDATED ELECTRICAL RACK: The new Model 1210 design allows the electrical rack back panel to swing down, exposing all electrical components for easy troubleshooting and maintenance. The consolidated design allows complete replacement of the electrical rack to be shipped to the end user for fast replacement in the field.

- EXPANSION SUPPORT: Additional support added for USB Wi-Fi Dual Band Ethernet (purchased separately) and 10/100 Wired Ethernet bulkhead connector (planned future expansion). USB Inkjet Printers are supported up to dotNET4.5 (low resolution printers via basic printer drivers).

- DESIGN IMPROVEMENTS: Components are updated to take advantage of the latest CNC capabilities and component materials for improved accuracy and machine longevity without cost increases.

- STREAMLINED MANUFACTURING: New streamlined process improves manufacturing turn-around time.

Features

- Windows Operating System

- Color touch-screen monitor for easy viewing

- Test-result tabular report lists each test result and the statistical analysis for the group of samples tested in an easy-to-read format

- Data logging capabilities add test curve output files as CSV, allowing you to see the force vs. deflection curve for each test

- Graphics and performance enhancements

- Increased dynamic response allows additional test specimens including glass, fiber, metals, and other extremely brittle samples

- Sample rate has increased to 5,000 samples per second, giving the machine a higher sensitivity and response

- Additional user settings to help with setting up printers and installing peripheral programs

- Data management is easy. Users can create their own specific identification numbers and view data at any time. Stored data can be re-displayed or printed as a table, histogram, or a control chart

- Platen opening limits are adjustable by user

- Select specific fixed parameter TAPPI specified tests (ECT, PAT, FCT, RCT, CMT, and CFC), eliminating operator error PLUS User-definable tests: Peak at Fallback, Peak at Deflection, and Force at Deflection

- When test stops the platen moves up automatically. There are two positioning speeds: fast and slow

- Scaled output converts measured force values to the appropriate TAPPI report units

- Automatic Zero

- RS-232 output data that can be used in a third party software, such as Microsoft Office/Excel

- Built in software load cell protection and adjustable platen positioning for fixture and machine protection

- USB pen drive, calibration restoration, and updates can be installed easily and used to back up data

- Calibration: Force, resolution, and speed are password protected but can be changed easily in the software calibration section of the program which allows on-site calibration service

- Precise flatness and parallelism is held within .0005”

- Units available in Empirical or metric

- Calibration Test Certificate provided per ASTM E 74

- Operation Manual

Specifications

- Capacity 0 – 1000 lbs

- Platen Size 6″ x 6″ x 3.125″

- Platen Speed 0 to 2 in/min

- Rupture Sensitivity 0 to 99%

- Accuracy .15% of reading or .05% of full scale

- Dimensions 22.0W X 17.0D X 24.5H inch, 589W X 432D X 622H mm

- Weight 120 lbs

- Power 120VAC or 220VAC (customer please specify) 50/60Hz (120VAC US PC Cable supplied by default, compatible with regional/voltage variants)

Units of Measure Supported

- LBS (LBF)

- PSI

- PLI

- PLF

- N

- Kpa

- kNm

- N/mz

Preview Software

Preview Emerson’s Software for Models 1210 & 2210. Windows Operating System and hardware adds accuracy, speed, is current with today’s technology, and provides storage for thousands of test results. PLUS you get additional reporting features, data logging capabilities, the ability to output files as .CSV and plot data points with MS EXCEL, advanced graphics, increased dynamic response, and much more!

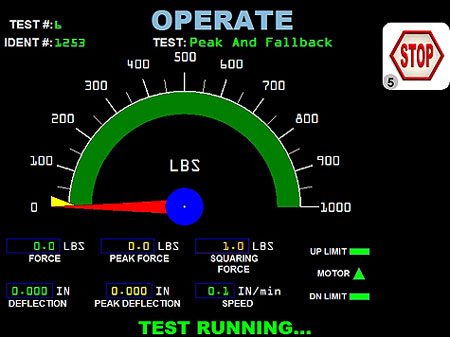

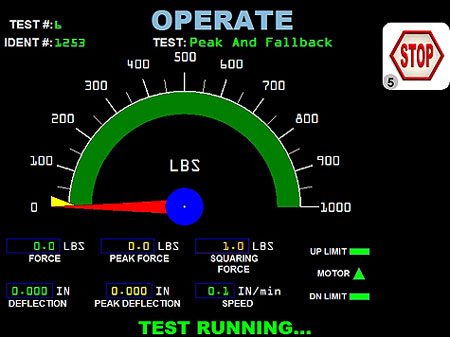

Preview +

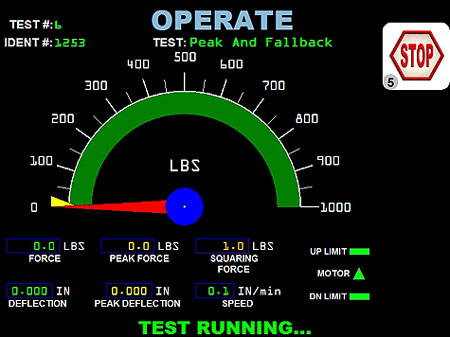

OPERATE SCREEN–This screen shows the machine running a test. It includes actual force, peak force, actual deflection, and peak deflection, selected squaring force, selected speed, and indicators showing the status of upper limits, lower limits, and that the motor is enabled.

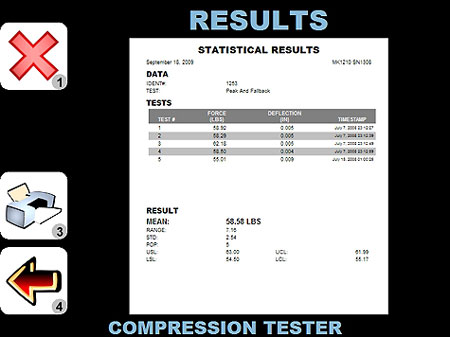

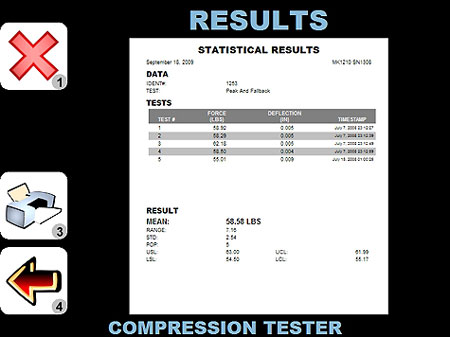

RESULTS SCREEN–This screen shows test data in text form (including peak force and deflection).

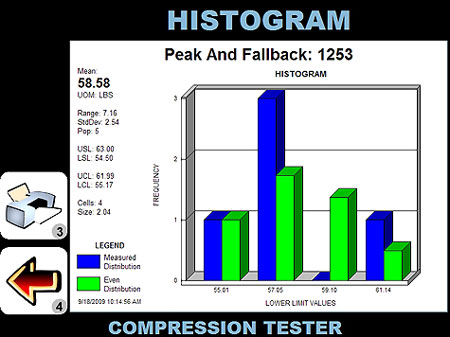

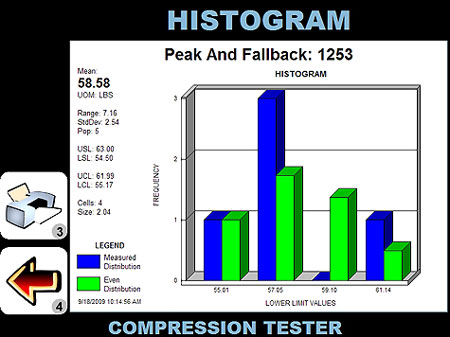

HISTOGRAM SCREEN–This screen lets you view test data in bar graph form.

Safety Features

- Rapid travel load applied : motor stops when 10LBS applied while platen closing at rapid speed

- Force and Deflection user limits

- Absolute force machine limit

- Watchdog failure kills motion

- Database verification and automatic rebuild and cleanup prevents corrupt data from creating unsafe conditions

- Physical Limit Rod travel limits

- Encrypted registry entries prevent machine tampering that may cause unsafe conditions

- Extensive machine guarding for safe operations

- Enhanced fault detection and monitoring

Statistical Results

- On screen and printed CONTROL CHART

- On screen and printed HISTOGRAM

- On screen and printed Statistical Report (text)

- Statistical grouping by TEST TYPE + user defined IDENT NUMBER

- Database backup for off-machine use

- Test charting per test created automatically when USB pen drive attached for detailed test analysis of force vs. deflection curves

- RS232 data logging for external data collection and analysis packages such as ASI DataMytez

Accessories/Options

- ECT Holding Fixture

- Ring Crush Test Fixtures

- Flat Crush Test Fixture

- A, B, C, & E Flute Pin Adhesion Fixtures, Selective

- A, B, C, & E Flute Pin Adhesion Fixtures, Non-selective

- Custom Spaced Pins Made to Order

- Custom Fixtures Made to Order

Emerson’s Model 2210 Crush Tester is an extremely versatile benchtop crush tester for both material and package testing. The Model 2210 is designed to test corrugated, tubes, cores, bottles, and cans for the packaging, plastic, and building products industries. Its test menu offers fixed parameter tests for standardized material testing (per TAPPI requirements) and user-defined tests for any combination of test parameters and failure modes. Model 2210 comes with high-speed computer, Windows Operating System, flat panel color display, and customized Emerson software that stores data and groups it for averaging, standard deviation, histograms, and control charts.

NEW Features

- NEW! Test-result tabular report lists each test result and the statistical analysis for the group of samples tested in an easy-to-read format

- NEW! Data logging capabilities add test curve output files as CSV, allowing you to see the force vs. deflection curve for each test

- NEW! Graphics and performance enhancements included

- INCREASED DYNAMIC RESPONSE allows additional test specimens including glass, fiber, metals, and other extremely brittle samples

- SAMPLE RATE has increased to 5,000 samples per second, giving the machine a higher sensitivity and response

- ADDITIONAL USER SETTINGS to help with setting up printers and installing peripheral programs

Features

- Windows Operating System

- Eight-inch, color, flat panel monitor displays real time force, deflection, and peak values

- Stored data can be re-displayed or printed as a table, histogram, or a control chart

- High load and deflection limits protect the machine and its fixtures from potential damage

- Fixed parameter tests: ECT, Pin Adhesion, Flat Crush, CMT, and CFC

- User-definable tests: Peak at Fallback, Peak at Deflection, Tensile, and Force at Deflection

- Rapid platen return and settable positioning allows for rapid, repetitive testing

- Scaleable output converts measured force values to the appropriate report units

- Automatic Zero

- RS-232 Output

- Printer output USB or Standard 25 pin

Specifications

- Capacity 2000 lbs

- Platen Size 13″ x 13″

- Stroke 16″ (optional 26″ opening)

- Platen Speed 0 to 2 in/min

- Rupture Sensitivity 0 to 99%

- Accuracy .15% of reading or .05% of full scale

- Dimensions 34″ x 47″ x 30″

- Weight 250 lbs

- Electrical 1 phase 120V/60Hz Optional 220V/50Hz

Units of Measure Supported

- LBS (LBF)

- PSI

- PLI

- PLF

- N

- Kpa

- kNm

- N/mz

Preview Software

Preview Emerson’s Software for Models 1210 & 2210. Windows Operating System and hardware adds accuracy, speed, is current with today’s technology, and provides storage for thousands of test results. PLUS you get additional reporting features, data logging capabilities, the ability to output files as .CSV and plot data points with MS EXCEL, advanced graphics, increased dynamic response, and much more!

Preview +

OPERATE SCREEN–This screen shows the machine running a test. It includes actual force, peak force, actual deflection, and peak deflection, selected squaring force, selected speed, and indicators showing the status of upper limits, lower limits, and that the motor is enabled.

RESULTS SCREEN–This screen shows test data in text form (including peak force and deflection).

HISTOGRAM SCREEN–This screen lets you view test data in bar graph form.

Safety Features

- Rapid travel load applied : motor stops when 10LBS applied while platen closing at rapid speed

- Force and Deflection user limits

- Absolute force machine limit

- Watchdog failure kills motion

- Database verification and automatic rebuild and cleanup prevents corrupt data from creating unsafe conditions

- Physical Limit Rod travel limits

- Encrypted registry entries prevent machine tampering that may cause unsafe conditions

- Extensive machine guarding for safe operations

- Enhanced fault detection and monitoring

Statistical Results

- On screen and printed CONTROL CHART

- On screen and printed HISTOGRAM

- On screen and printed Statistical Report (text)

- Statistical grouping by TEST TYPE + user defined IDENT NUMBER

- Database backup for off-machine use

- Test charting per test created automatically when USB pen drive attached for detailed test analysis of force vs. deflection curves

- RS232 data logging for external data collection and analysis packages such as ASI DataMytez

Accessories/Options

- ECT Holding Fixture

- Flat Crush Test Fixture

- A, B, C, & E Flute Pin Adhesion Fixtures, Selective

- A, B, C, & E Flute Pin Adhesion Fixtures, Non-selective

- Custom Spaced Pins Made to Order

- Custom Fixtures Made to Order

Emerson Apparatus can customize any of our Compression Testers to meet your specific size requirements and software/testing needs (pictured: modified 2210 Compression Tester). MORE +

Emerson Apparatus can customize any of our Compression Testers to meet your specific size requirements and software/testing needs (pictured: modified 2210 Compression Tester). MORE +

New hardware and software adds accuracy, speed, and provides storage for thousands of test results. PLUS you get additional reporting features, data logging capabilities, the ability to output files as .CSV and plot data points with MS EXCEL, and various graphics and performance enhancements. MORE +